-

Automatic Honey Stick Hot Sauce Bottle Filling Machine

This sauce filling machine dedicated for paste material jam, like ketchup, tomato sauce, chocolate sauce, cheese, chilli sauce, cooking oil, peanut oil, olivia oil, coconut oil, sesame oil, corn oil and also lubricant oil.

This filling machine is mainly applicable for filling thicker liquid into glass bottle, plastic bottle, metal can etc. Such as ketchup, mayonnaise, honey, fruit puree etc. The filling valve adopt the piston type and each filling valve will be controlled separately.

It has characteristics of more compact in structure, more reliable and safety in operation, ease in maintenance.It has an infinite variable speed device, so its output can be changed freely.

-

Tomato ketchup/paste/sauce filling machine production line

The machine adopts PLC control, according to the filling bottle, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic servo piston filling machine advantages, also the widened the range of filling material. Such as filling material contains particles, long strips of solid content, also can be a very effective filling. This machine adopts serve ball-screw system to drive the piston cylinder. It’s widely used in Food, Chemical, Medical, Cosmetics, Agrochemical industry, applicable for filling liquid, especially for high viscosity material and foamy liquid, such as: Oil, Sauce, Ketchup, Honey, Shampoo, Lotion Lubricant oil, etc.

-

small scale pharmaceutical medical vial liquid filling capping machine

This compact line is specially designed for the requirement of low output and small serial production with various sizes of the container, the major machine parts procured from well-know brand, adopt smart control system. The line benefits our customers by its few change parts and changing parts quickly.

The entire synchronized filing line in stable running, easier operation, low noise, no pollution to production environment, the designing and manufacturing are being in compliance with ISO standard, cGMP guideline, FDA’s CFR211.67a regulation, CE standard, Principle of Human Machine Engineering: oRABS, cRABS, lsolator system are possible to provide optionally. The container sizes applicable range from 2m-100ml

with maximum production speed of the whole line up to 120vias/min.

-

Automatic Filling and Capping Machine for Injection Vials Sterile Filling Machine line

Automatic Vial Filling & Capping Machine BotCN-Cap 4 is specially designed for small-quantity filling, stopper pressing and seal capping in pharmaceutical, light chemical, foodstuff and other industries. It can finish the production process of a series of automatic steps–vial feeding, metering and filling, stopper pressing, seal cap feeding and capping, etc. The whole machine is made of 304# stainless steel with strong resistance to corrosion. Due to PLC and HMI, it is easy and convenient to operate the machine. Besides, as the machine is driven by servo motor and vials are filled by peristaltic pump, the machine has high precision, fast speed and high output. The equi-index plate vial-feeding mechanism has high positioning accuracy. The loading quantity of peristaltic pump can be adjusted in a wide range. The components of drive system are processed with high-quality steel, of which the surface is treated to avoid blackening and the hardness is strengthened to improve the service life. In addition, the machine is equipped with the frame made of 304# stainless steel, and a protective cover composed of PC transparent boards. -

Automatic 36000cph high level can depalletizer for beverage line

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

The talent team of Ipanda Intelligent Machinery Garhers product experts,sales experts and after-sales service staffs,and upholds the business philosophy of “High performance, Good service,Good prestige”.Our engineers are responsible and professional with more than 15 years experience in the industry.We will according to your product samples and filling material return the real effect of packing Until the machine work well ,we will not ship it to your side.Aimed at offering high level products to our customers, we adopt the SS304 material, reliable components for the products. And all the machines have reached CE standard. Overseas after-sales service is also available, our engineer has gone for many countries for service support. We are always striving to offer high quality machines and service to customers.

Why Choose Us

l Dedication to Research & Development

l Experienced Management

l Better understanding of Customer requirement

l One Stop solution provider with Broad Range Offering

l We can supply OEM&ODM design

l Continuous Improvement with Innovation

-

Automatic 4 Heads Face beauty Cream Vertical Cosmetics Paste Bottle Filling Machine With Feeding Pump

This Cosmetics Paste Bottle filling and capping machine 50ml vial syrup filling machine used for the filling production line of reagents and other small-dose products. It can realize automatic feeding, high-precision filling, positioning and capping, high-speed capping, and automatic labeling. This machine adopts mechanical rotation to ensure accurate and stable operation, low noise, low loss, and no air source pollution. The whole machine is made of stainless steel 304, which meets GMP requirements.

Features

1. The bottle entering mode can be in different scheme based on the user’s requirement and bottle shape feature.2. Adopting 316L stainless steel piston cylinder, and ceramic plunger type cylinder or designated method by user for precision filling, the filling accuracy is ±0.5~1%3. The function of automatic alarm and stop when filling needles deviate from bottle neck.4. The unique inlet and outlet check valve and the precision machining to ensure not dropping when filling. The filling needle will move up and down or submersible filling, to prevent liquid bubbling or splashing.5. The specially designed lid and lid feeding matched automatic precisely up with capping, accurately complete each mechanical motion cycle, such as crabbing lid, capping, and others, the whole process in unison, stably and reliably, without dropping lid.6. The whole production line of intelligent control has the function of chain control for upstream and downstream working equipment.

7. The surface of main parts of the whole production line is made of SUS 304 stainless steel, hardness of anodized aluminum alloy, non-toxic polymeric materials, etc. which comply with GMP rules. -

Automatic Shampoo Bottle Filling Machine

Automatic Shampoo Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

The machine is facilitate to maintain.not need any tool. It’s very easy to disassemble and install,cleaning.Adjustment volume could be large range to little range and then to fine adjustment.Could achieve no bottle or lack bottle not filling.High filling volume precision.

-

Automatic Pharmaceutical Cbd Essential Oil Filling Machine Line

Automatic vial bottle monoblock liquid filling, stoppering and capping machine is a monoblock liquid filling machine in our company products. The filling, stoppering(as per requirest) and capping can be work together on one machine. This machine consists of cylinder positioning device, bottle outlet track and electric control system. It depends on cylinder to position the bottles, cylinder to push the filling needle up and down to carry out the filling function.

-

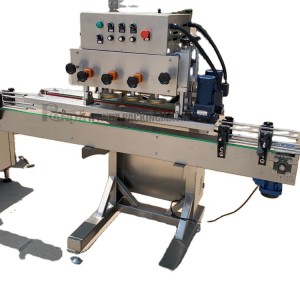

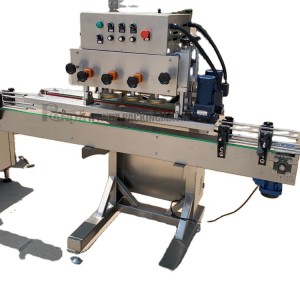

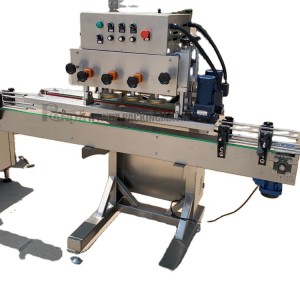

Automatic Tomato Paste Chili Jam Paste Filling Machine

The machine adopts PLC control, according to the filling bottle, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic servo piston filling machine advantages, also the widened the range of filling material. Such as filling material contains particles, long strips of solid content, also can be a very effective filling. This machine adopts serve ball-screw system to drive the piston cylinder. It’s widely used in Food, Chemical, Medical, Cosmetics, Agrochemical industry, applicable for filling liquid, especially for high viscosity material and foamy liquid, such as: Oil, Sauce, Ketchup, Honey, Shampoo, Lotion Lubricant oil, etc.

-

Automatic capping machine for trigger cap

The capping machine can cap different sizes and shapes of lids,the capping height of the machine can be adijusted to fit your machine. It is widely used in industries of cosmetics, food, beverage, medicine, biotechnology,etc.

-

Automatic Crown Capping Machine

The Automatic Crown Capping Machine is used to affix standard crown caps to glass bottles. It is mostly used in pharmaceutical, chemical and beverage industries where small production batches are required. Further, this machine also used in laboratories where test batches are made. We can provide you these Automatic Crown Capping Machine along with the assurance of quality. Our entire range is quality tested by a dexterous team of quality controllers before they let are allowed to dispatch our premises.

-

Automatic Linear Screw Capping Machine Inline Spray Pump Bottle Capper Cap Sealing Machine Price

The capping machine can cap different sizes and shapes of lids,the capping height of the machine can be adijusted to fit your machine. It is widely used in industries of cosmetics, food, beverage, medicine, biotechnology,etc.