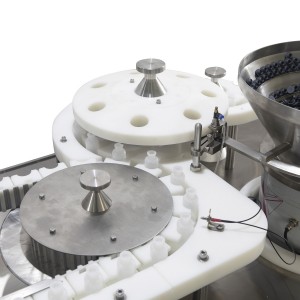

Automatic Filling and Capping Machine for Injection Vials Sterile Filling Machine line

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

The talent team of Ipanda Intelligent Machinery Garhers product experts,sales experts and after-sales service staffs,and upholds the business philosophy of “High performance, Good service,Good prestige”.Our engineers are responsible and professional with more than 15 years experience in the industry.We will according to your product samples and filling material return the real effect of packing Until the machine work well ,we will not ship it to your side.Aimed at offering high level products to our customers, we adopt the SS304 material, reliable components for the products. And all the machines have reached CE standard. Overseas after-sales service is also available, our engineer has gone for many countries for service support. We are always striving to offer high quality machines and service to customers.

Why Choose Us

l Dedication to Research & Development

l Experienced Management

l Better understanding of Customer requirement

l One Stop solution provider with Broad Range Offering

l We can supply OEM&ODM design

l Continuous Improvement with Innovation

|

Model

|

Suitable sizes

|

Output

|

Filling heads

|

Plugging heads

|

Power

|

Net weight

|

Overall dimensions

|

|

ABGZ12

|

2-30ml vial

|

6000-24000pcs/h

|

12

|

24

|

17kw

|

2000kg

|

4670*2150*1850mm

|

|

ABGZ12/10

|

6000-20000pcs/h

|

10

|

16kw

|

||||

|

ABGZ12/8

|

6000-16000pcs/h

|

8

|

15kw

|

||||

|

ABGZ12/6

|

2-100ml vial

|

3000-12000pcs/h

|

6

|

12/24

|

14kw

|

||

|

ABGZ6

|

2-30ml vial

|

3000-12000pcs/h

|

6

|

14kw

|

1500kg

|

3950*1950*1850mm

|

|

|

ABGZ6/4

|

3000-7200pcs/h

|

4

|

13kw

|

||||

|

ABGZ6/2

|

2-100ml vial

|

1000-3600pcs/h

|

2

|

12kw

|

|

Material

|

Stainless Steel

|

|

Customized

|

Accept

|

|

Service

|

OEM and OEM

|

|

Package

|

Standard wooden packing for sea shipping

|