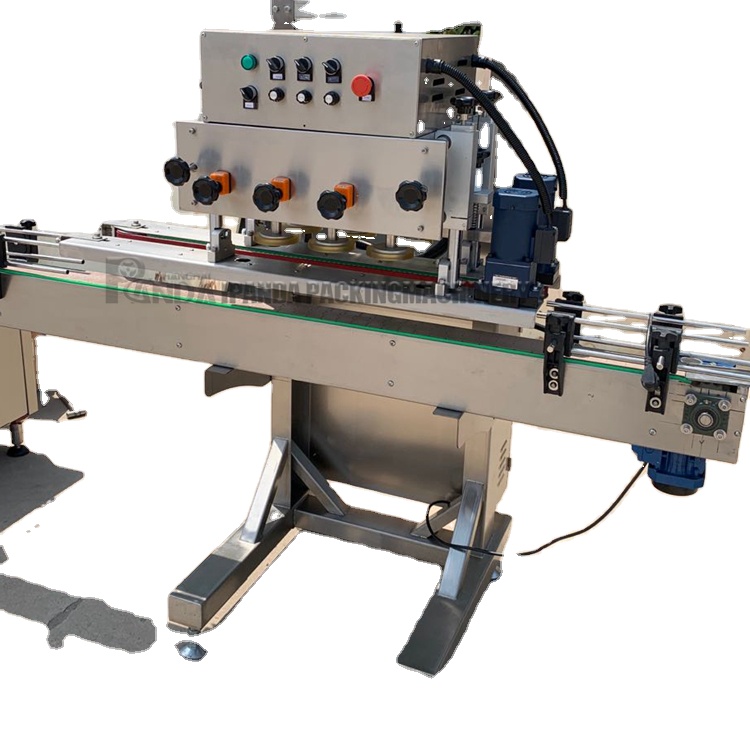

Automatic capping machine for trigger cap

| Applied bottle range | 20-150mm |

| Applied cap size | 12-70mm |

| Yield of capping | ≥99% |

| Power supplied | 220V 50Hz |

| Power | 2000W |

| Air pressure | 0.4-0.6MPa |

| Weight | About 850Kg |

| Dimension (L*W*H) | 3000*1100*1600mm |

| Production capacity | 3000-6000 bottles/hour |

- -Adopt agile module combination, new ideal design, suit to various bottle and cap-rotating.

- -Not need to change parts, easily adjustable.

- -Easy operation and convenient for maintenance.

- -Three group capping consist of first rotating and re-rotating the degree of moment may be adjusted singly. Ensure that will be tight. The capping machinery has clutch to avoid the cap over-rotating.

- -Two sets of bottle nipping and annular belt structure, Good effect for some bottles erecting unsteadily.

- -Cap arranging part, conveying part, cap-rotating, belt for bottle, nipping, all of speed can be governing separately, which is more utility.

- -Choosing automatic cap-sender and cap hopper

- -The vacuum capping machine is designed according to requirements of GMP.

6 Wheels

1. Each wheels speed is indivadually adjustable, requency controlling

2. The wheels can run in opposite direction to make cap fitting the bottles well if necessary

3. Wheels are made of soft material to prevent caps from damage

4. Wheels are horizontally adjustable for different sizes of caps

5. Wheels are vertically adjustable for bottles of different height

6. Each wheels driven by one motor

Two-layer Bottle Clamp Belt

The double belts height is adjustable to fit differnet sizes bottles.and the angle is adjustable according to the bottle shape, more stable. Speed is frenquecy contolled to match the conveyor and capping speed

Motors

1. 6 motors for 6 capping wheels, and the motors can change to servo motor for torgue adjustable if customer need

2. 2 motors for botle clamping belt

3. 1 motor for machine height adjutment up and down

4. Capping torgue is adjustable for option

Write your message here and send it to us