New Design Automatic Perfume Filling Capping Machine for Plastic Bottle and Glass Bottle

This automatic filling capping machine is in the introduction and absorption of foreign advanced technology on the basis, by my company independent research and development of a professional for automatic bottle filling, capping.

This machine is mainly suitable for various kinds of small dose of liquid filling and capping, such as injection, perfume spray, etc. widely used in food, pharmaceutical, chemical industry and research fields.

|

Voltage

|

220V/50Hz

|

|||

|

Power

|

2.0 kw

|

|||

|

Filling range

|

1-50ml

|

|||

|

Filling error

|

≤±1%

|

|||

|

Filling head

|

1

|

|||

|

Capping head

|

2(inner lid and outer cap)

|

|||

|

Capacity

|

1500-2000BPH

|

|||

|

Dimension:

|

2500*1200*1750mm

|

|||

|

Net weight

|

600 kg

|

|||

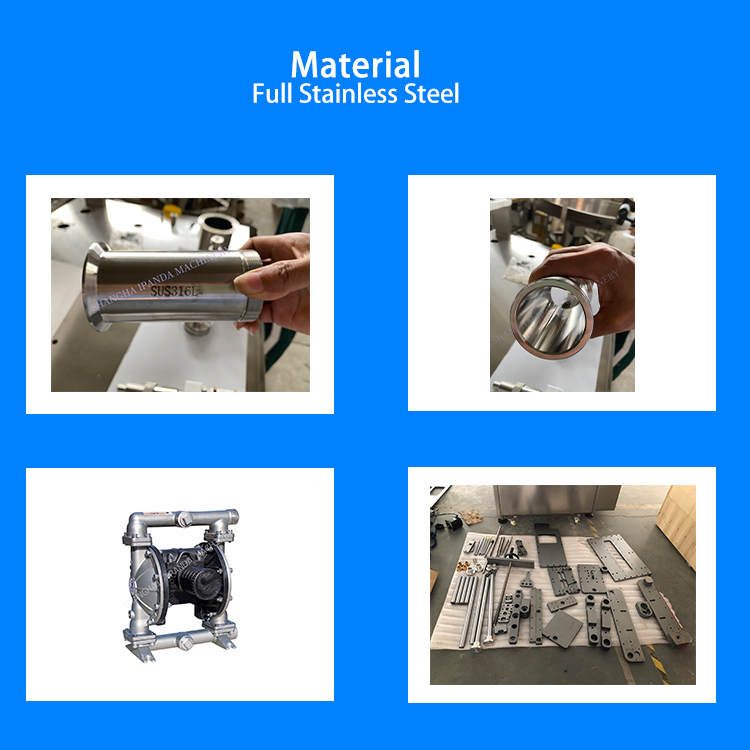

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

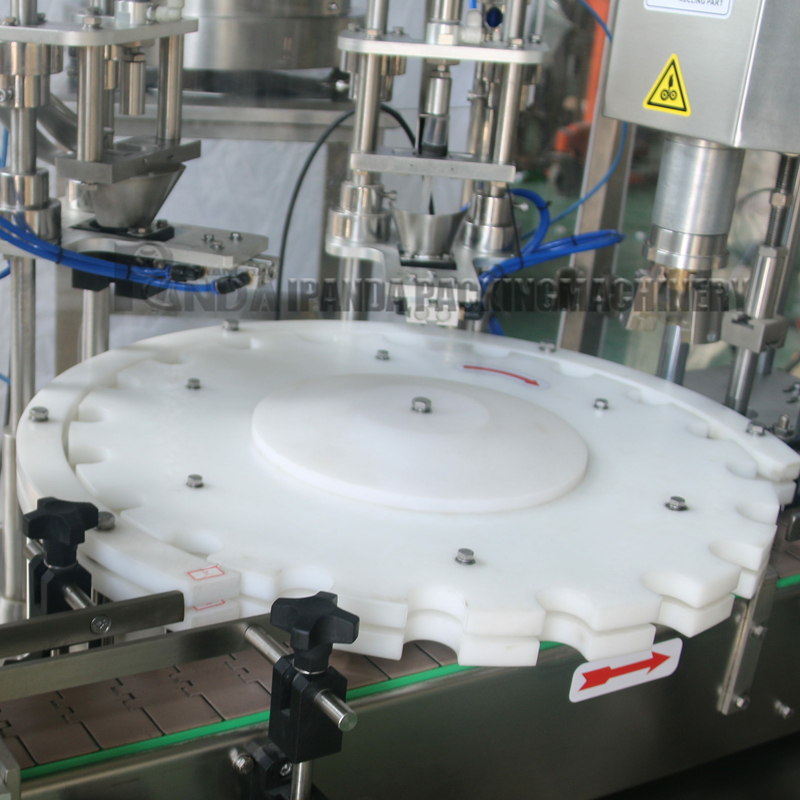

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5. Siemens Touch screen/PLC

6.No bottle no filling/plugging/capping

Rotary table, No bottle no filling, No cap auto stop, easy for trouble shooting, No air machine alarm, Multiple parameters setting for different caps.

Filling system: lt can achieve automatic stopping when bottles are full, and automatic starting when bottles are lacked on the belt conveyor.

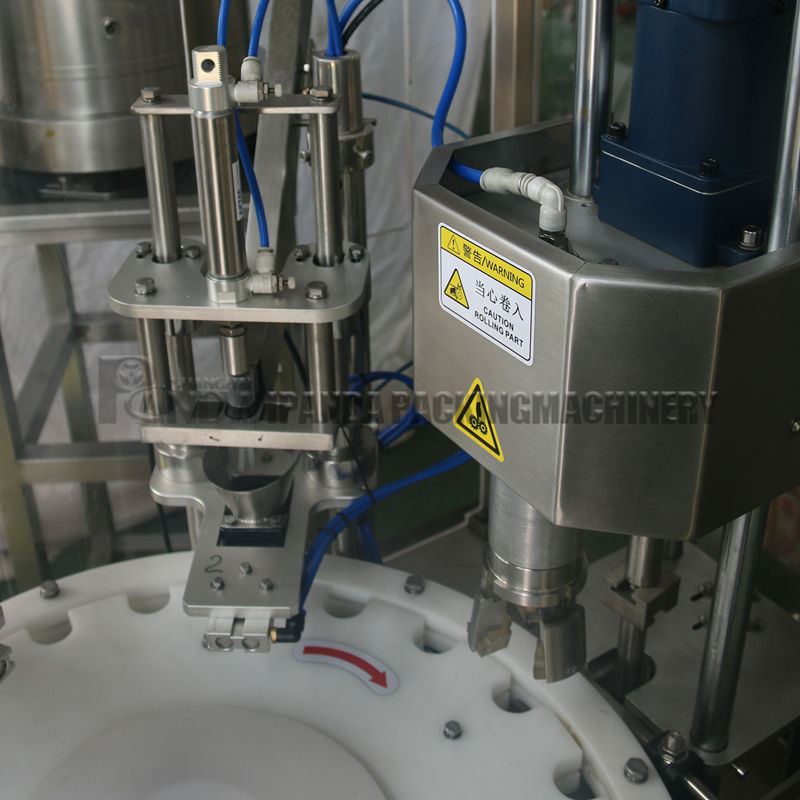

Filling head: Our filling head have 2 jackets You can see the filling split connect with 2 pipes.The outside jacket connect with vacuum suction air pipe.The inner jacket connect with filling perfume material pipe.

Capping station

Capping head all will customize according to customer different cap.

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs