Automatic essential oil bottle filling machine

Filling part of the machine can be used peristaltic pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. It is suitable for products of liquid such as essential oil, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent etc.The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements.

| Applied Bottle | 5-200 ml (can be customized ) |

| Productive Capacity | 20-40pcs/min 2 filling nozzles |

| 50-80pcs/min 4 filling nozzles | |

| Filling Tolerance | 0-2% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V ,50HZ,customize |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

Touch screen can be showed in English,Spanish,Rassina,Italian and others language,can be customized according to your requirement.

1. Filling part metering peristaltic pump filling to ensure filling accuracy.

2.Filling part of the needle probe into the filling, to prevent liquid overflow, frothing, etc., filling needles made of 316L.

3. Gasser disc using the positioning stopper, and modified into new pneumatic suction plug, boom, put the plug than conventional pneumatic corking yield, will not damage the inner plug, improve the passing rate.

4. Stamped part is stamped disc positioned to ensure precision stamped, and with sensors, no less than a bottle cap.

5. Capping part transverse torque capping, capping adjustable intensity, auto-skid device, not galling bottle; bottle not turn with the turntable will not scratch the bottle, effective protection of the beautiful packaging materials and equipment hand wheel adjustment devices (including the position of the display), adjust the height of different aspects of production specifications.

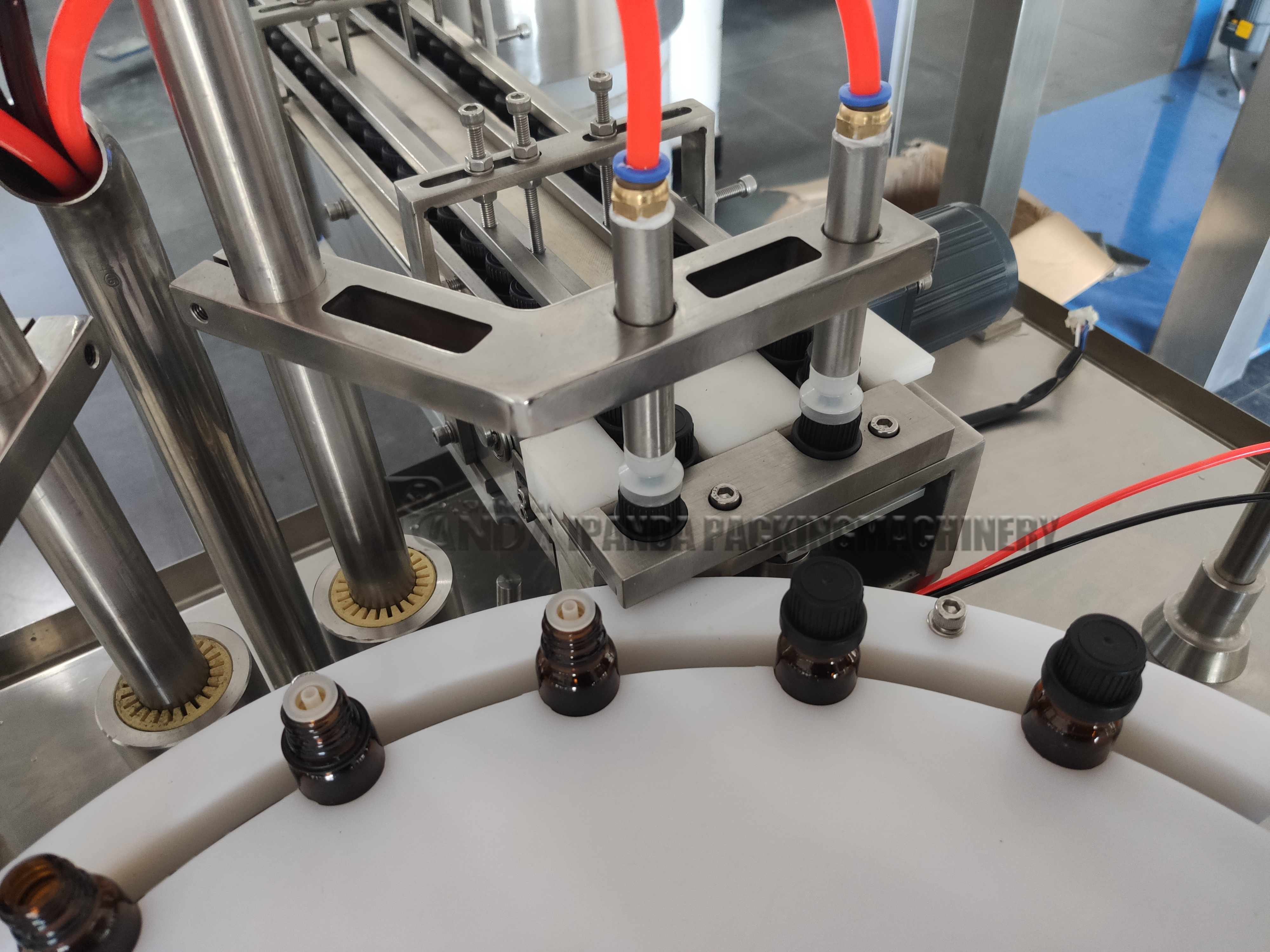

Filling part

Adopt SUS316L Filling nozzles and food grade silicon pipe

high precision. Filling zone protected by interlock guards for safety registration. Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

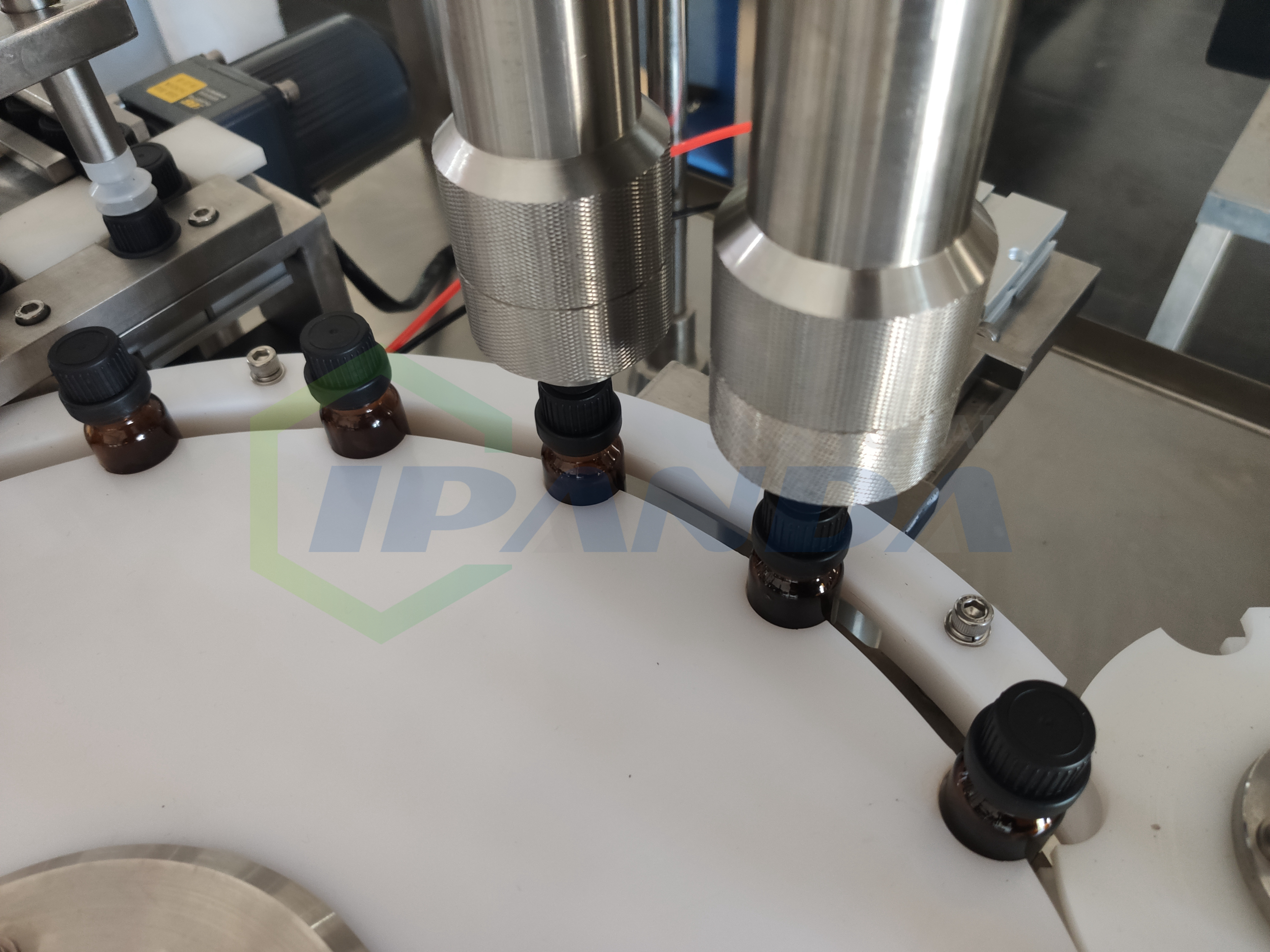

Capping Part: Inserting inner cap-putting cap-screw the cap

Capping unscrambler:

it's customized according to your caps and droppers.

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

The talent team of Ipanda Intelligent Machinery Gathers product experts,sales experts and after-sales service staffs,and upholds the business philosophy of “High performance, Good service,Good prestige”.Our engineers are responsible and professional with more than 15 years experience in the industry.We will according to your product samples and filling material return the real effect of packing Until the machine work well ,we will not ship it to your side.Aimed at offering high level products to our customers, we adopt the SS304 material, reliable components for the products. And all the machines have reached CE standard. Overseas after-sales service is also available, our engineer has gone for many countries for service support. We are always striving to offer high quality machines and service to customers.

FAQ

Q1: What is your company's main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q6:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q7:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.