Fully automatic small vials nail polish filling and capping machine

High quality for small glass bottle nail polishing filling capping machine with automatic system is a filling, the inner plug, inside tamponade, on the cover, unscrew the cover, the main part of the composition of PLC control. The machine through the cam drive, positioning accuracy, stable transmission. PLC automatic control filling, internal tamponade, capping the whole process. Automatic injection molding machine can be formulated by blowing directly into the filling system, to prevent cross-infection, the entire process is completed under sterile conditions. Without washing and drying. This machine is suitable for nail polish, nasal drops, ear drops, essential balm and other small dosage formulation filling .

The equipment is ideal for filling small volume bottles, we customize machine for different size and shape of bottles, both glass and plastic are OK. It is widely used in Cosmetics (essential oil, perfume, nail polish, eye drop etc) chemical (glass adhesive, sealant, white latex, etc.) industries etc.

|

Model |

SHPD2 |

SHPD4 |

|

Filling head number |

2 |

4 |

|

Filling volume |

2-100ml |

2-100ml |

|

Working speed |

5-35 bottles/min |

10-70 bottles/min |

|

Filling accuracy |

≤ ±1% depends on proucts |

≤ ±1% depends on proucts |

|

Pass rate |

≥ 98% |

≥ 98% |

|

Power supply |

1ph 220V, 50/60Hz |

1ph 220V, 50/60Hz |

|

Power |

2.8KW |

3.0 KW |

|

Net weight |

850kg |

1000kg |

|

Overall dimension |

L6500 × W1800 × H1600mm |

L4600 × W4800 × H1600mm |

-

-

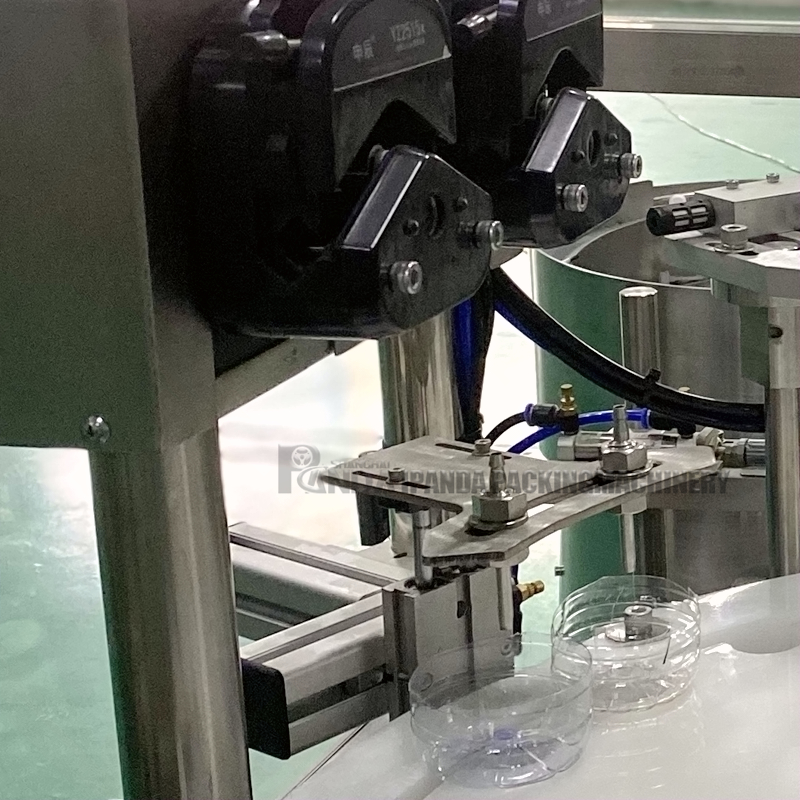

- This machine adopts mechanical/pneumatic arm to screw capping nozzle(Customized according to specific caps), equipped with automatic sliding device, to prevent the cap damaging.

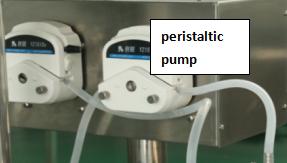

- Peristaltic pump or piston pump filling(depends on products density), measuring precision, convenient manipulation.

- Filling system has function of suck back, prevent the liquid leak through.

- Color touch screen display, PLC control system, no bottle no filling (only peristaltic pump) / no adding plug/ no capping.

- Main electrical elements like PLC,touch screen, main motor, adopts foreign well-known brand.

- Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

-

Filling part:

Adopt SS304 filling nozzles and food grade Silicone tube.It's meet CE Standard.Filling nozzle dive into bottle to fill and rise slowly to prevent foaming.

Peristaltic pump filling, measuring precision, convenient manipulation;

Capping part: Put the brush plug-

Capping part:screw the cap