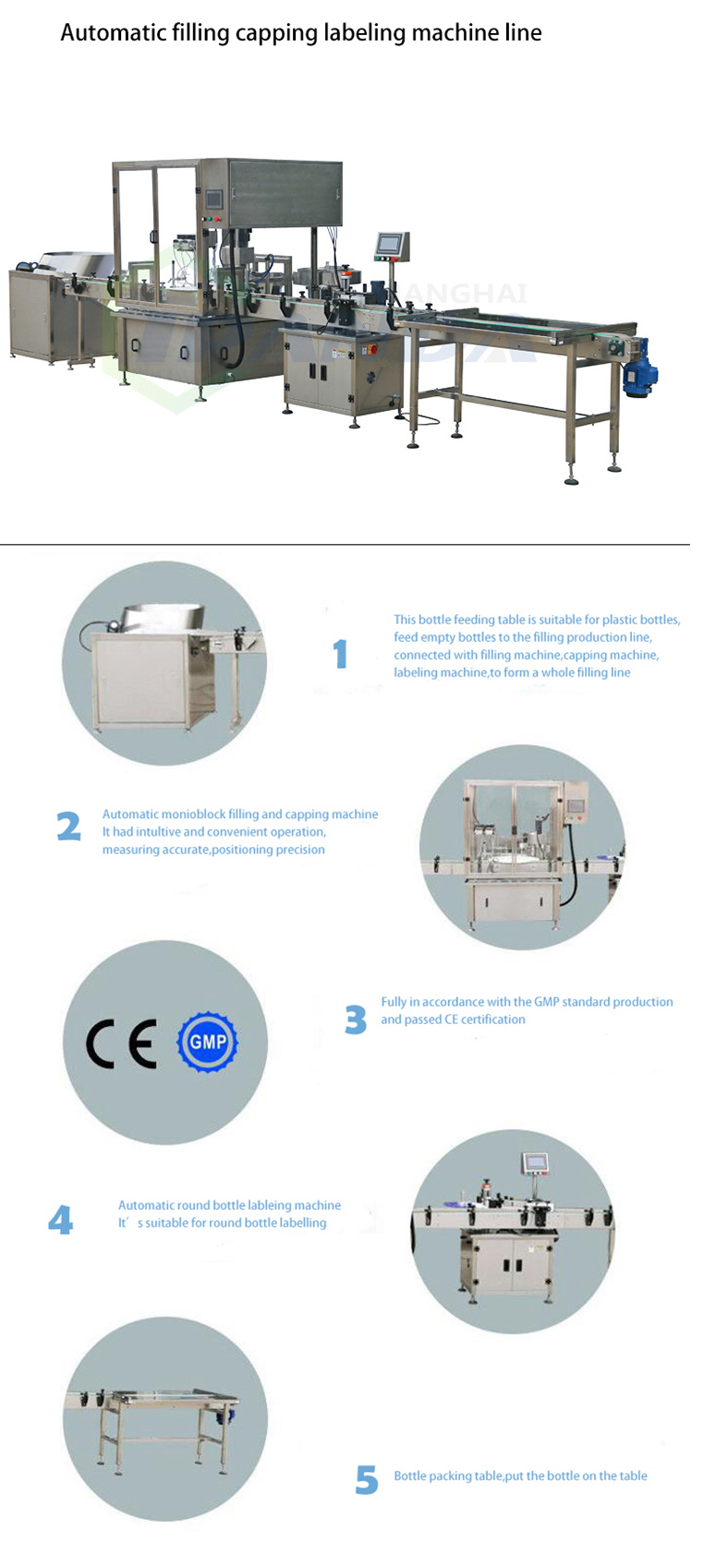

Automatic Pharmaceutical Eye Drop Liquid Filling Sealing Machine Production Line

It is an automatic equipment,it is suitable for automatic filling, stopper inserting and capping machine with of 5ml 10ml 15ml round and flat plastic eye drop bottles. All capping and filling is sterile production under laminar flow class A . we can also add rejection device,this part can detective no plugger and no liquid into the plastic bottle,if no, then the machine can rejection the bottles by itself automatically.

| Main parameter of the machine | |||

| Name | Filling capping machine | Filling volume | 5-250ml,can be customized |

| Net weight | 550KG | Filling heads | 1-4 heads,can be customized |

| Bottle diameter | Can be customized | Filling speed | 1000-2000BPH,can be customized |

| Bottle height | Can be customized | Voltage | 220V,380V ,50/60GZ |

| Filling accuracy | ±1ml | Power | 1.2KW |

| Bottle material | Glass ,plastic bottle | Working pressure | 0.6-0.8MP |

| Filling material | Eye drop,e-liquid,cbd oil | Air consumption | 700L per hour |

1.The unscrambler is a new design, completely replacing manual work;

2.The filling part adopts peristaltic pump or ceramic pump imported from Britain, with high filling accuracy, stable filling volume, automatic stop without bottle, no inner plug and no outer cover, adopting frequency conversion speed regulation;

3.The self-adhesive labeling machine has high labeling accuracy, automatic stop alarm without bottle, printing cleaning, and output counting function.

4.Fully comply with the new version of GMP certification requirements.

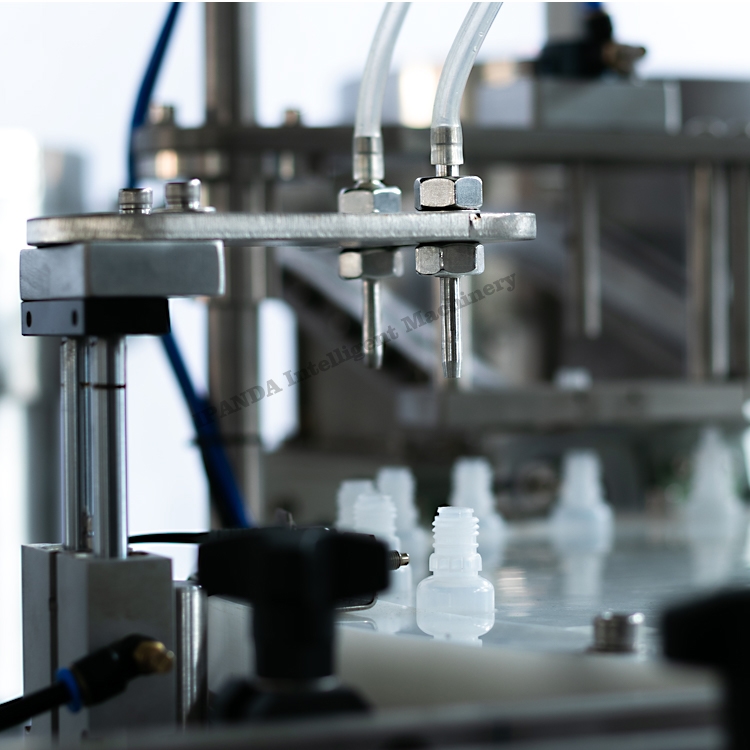

Adopt SS3004 filling nozzles and food grade Silicone tube.It's meet CE Standard.

Adopt Peristaltic pump: It's suitable for fluid filling.

Adopt Cap Unscrambler, it's customized according to your caps and droppers.

Capping part: Put the inner plug-put the cap-screw the caps.

Adopt magnetic torque screwing capping: sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

Order guide:

There are many types of filling machine,we need to know more details about your products in order that we can recommend the most suitable machine for you.Our questions as below:

1.What's your product?Please send one picture to us.

2. How many grams do you want to fill?

3.Do you have requirement of capacity?

Click the below picture,you can see our factory details