Automatic chocolate paste filling machine with glass cover

How It Works:

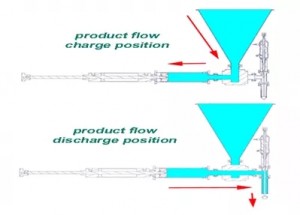

The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper.

The linear type filling machine is suitable for various viscous and non viscous and corrosive liquid, widely used in plant oil, chemical liquid, daily chemical industry quantitative small packing filling, linear filling, electromechanical integraton control, replacement of species is quite convenient, unique design, superior performance, other in conformity with the concept of international machinery and equipment.

|

Data sheets |

Details |

| Max filling speed | filling 200ml, 2400~3000 pcs/hour, speed will be different when bottle shape and neck size and the filling material forming and other physical property CUSTOMIZED |

| Applicable bottle diameter size |

Φ20 ≤D≤Φ100mm |

| Applicable bottle height size | 30≤H≤300 mm |

| Filling dose | 100~ 1000ml |

| Filling accuracy | ±1% |

| Voltage | AC220V, single phase, 50/60HZ |

| Power | 2.0KW |

| Working pressure | 0.6MP |

| Air consumption | 600L one hour |

| Net weight | 850 Kgs |

| Machine size(L*W*H) | 2000*1200*2250mm |

| Machine direction | from left to right |

| Operation process | put products on conveyer—>Block bottles—> sensor count the empty bottle—> 6 bottle come into the filling station —>lock bottles —>starting filling —> filling finished —> loose Block bottles—> Output bottles |

-

1. It adopt the piston type metering pump to filling; the pump structure using quick-connect disassembly mechanism, easy to clean and disinfect;

2. Piston type metering pump piston rings made of tetrafluoroethylene;

3. PLC control system, frequency control, full automation;

4. It is easy to adjust the filling amount, can be slightly adjusted for each metering pump; easy to operate, fast adjustment;5. With agitate in the tank, it will stir the material clockwise and counterclockwise direction;

6. Filling cylinder adopts rotary valve type piston pump to effectively prevent wire drawing and drip;

7. To ensure the bottles and filling nozzles are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable. No bottle no filling.

8. The feed tank adopts double-jacket hopper with stirring9, If you need, we could equipped with the heating system on tank.

10. For chocolate spread filling machine, the tank and the piston pump all adopt the heating system.

pls tell us your chocolate filling temperature ahead.

Food (olive oil, sesame paste, sauce, tomato paste, chili sauce,butter,honey etc.) Beverage( juice, concentrated juice). Cosmetics (cream, lotion,shampoo, shower gel etc) Daily chemical (dishwashing, toothpaste, shoe polish, moisturizer, lipstick, etc.), chemical (glass adhesive, sealant, white latex, etc.), lubricants, and plaster pastes for special industries The equipment is ideal for filling high-viscosity liquids, pastes, thick sauces, and liquids. we customize machine for different size and shape of bottles.both glass and plastic are OK.

Adopt SS304 or SUS316L filling nozzles

Filling mouth adopts pneumatic drip-proof device, filling no wire drawing, no dripping;

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Filling head adopts rotary valve piston pump with the function of anti-draw and anti-dropping.