30Ml Essential Oil Perfume Bottle Liquid Filling Capping Machine

The machine is an auto-liquid filling devise which is composed of PLC, human-computer interface, and optoelectronic sensor and air-powered. Combined with filling, plug, capping and screwing in one unit. It has the advantages of high accuracy, stable performance and greater versatility under extreme operating conditions which enjoys a high prestige. It has been widely applied in areas of pharmaceuticals industry.

| Applied Bottle | 5-200 ml (can be customized ) |

| Productive Capacity | 20-40pcs/min 2 filling nozzles |

| 50-80pcs/min 4 filling nozzles | |

| Filling Tolerance | 0-2% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V ,50HZ,customize |

| Power | 1.5KW |

| Net Weight | 600KG |

| Dimension | 2500(L)×1000(W)×1700(H)mm |

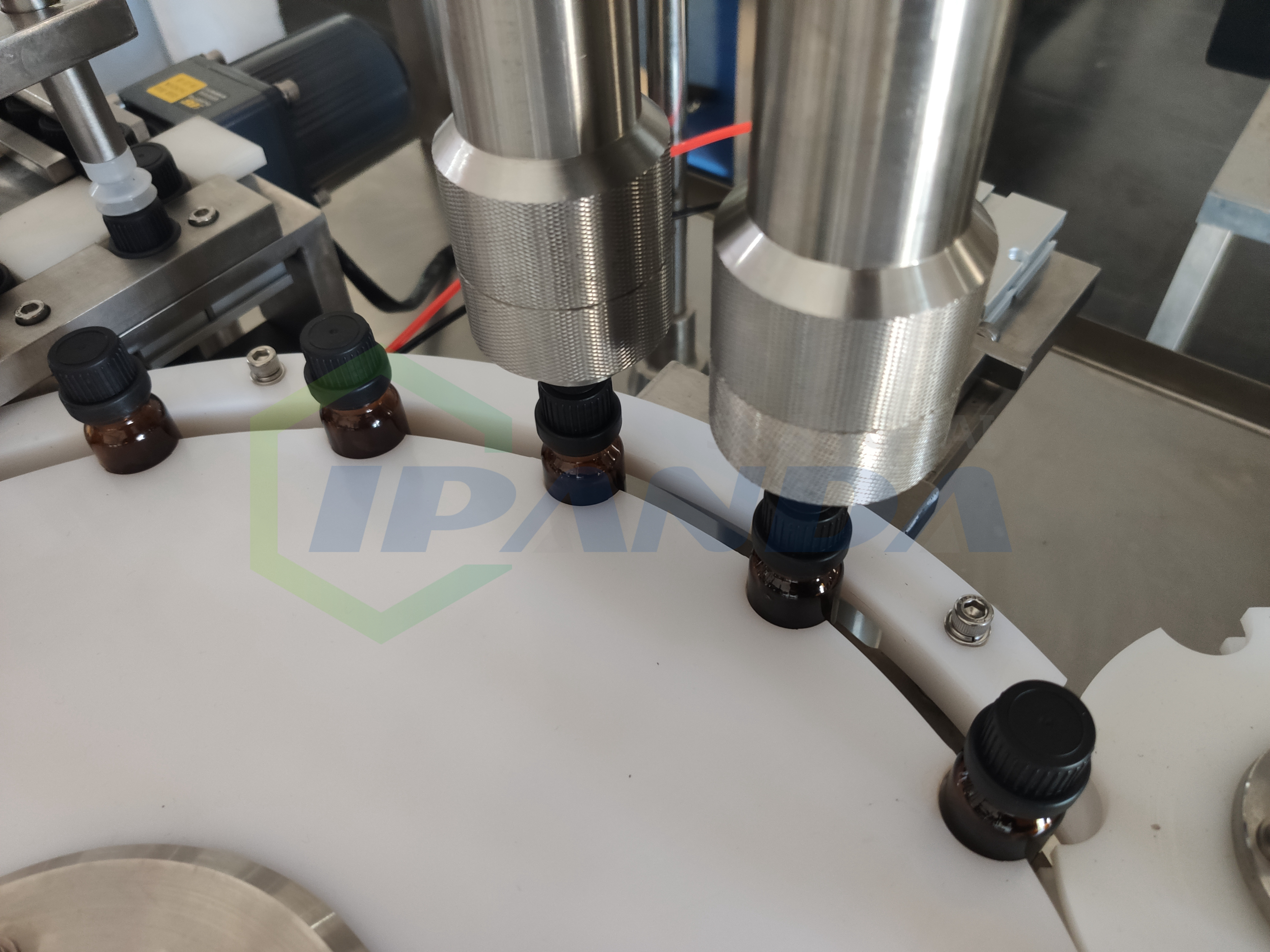

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

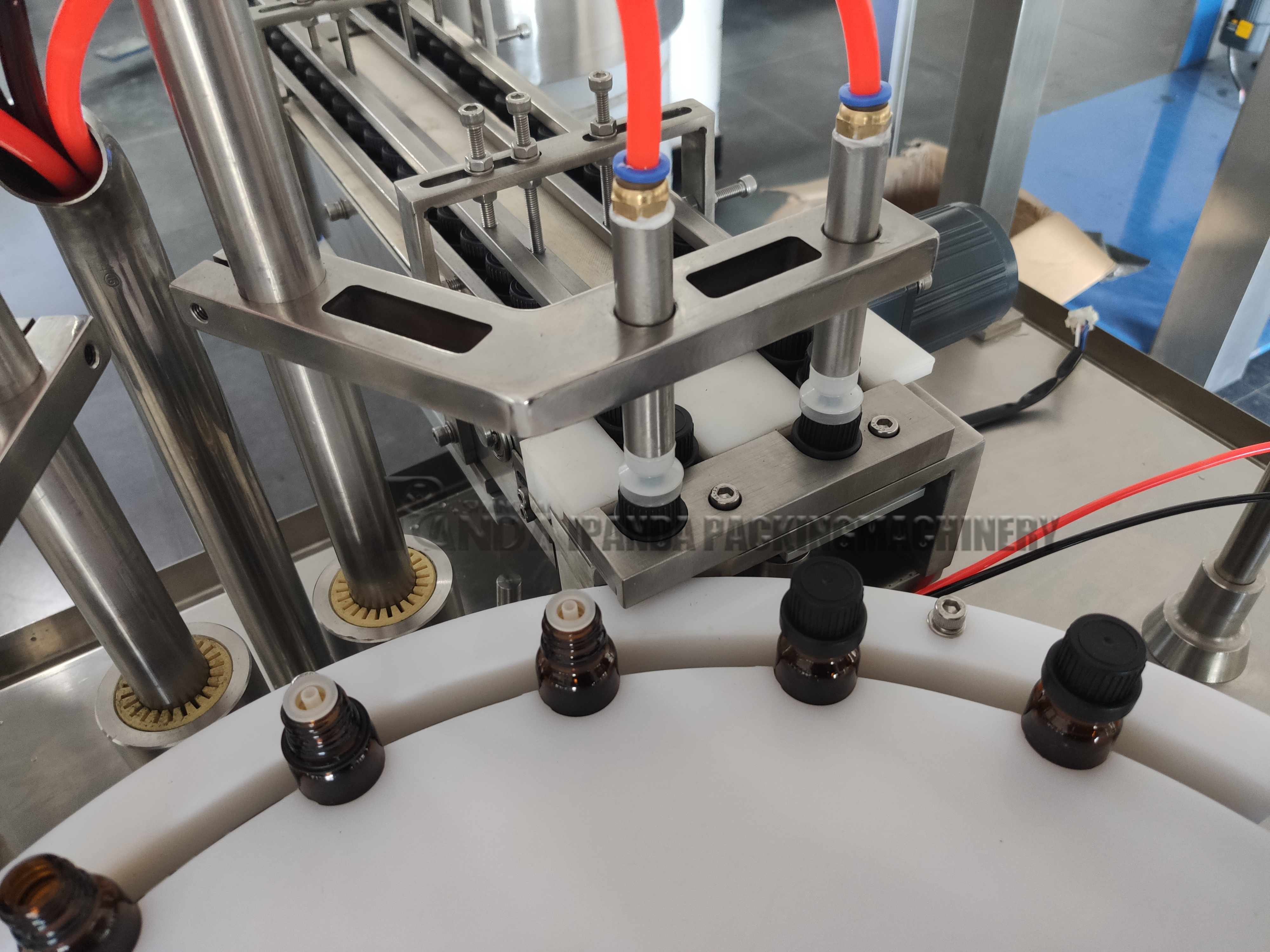

Filling part

Adopt SUS316L Filling nozzles and food grade silicon pipe

high precision. Filling zone protected by interlock guards for safety registration. Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

Capping Part: Inserting inner cap-putting cap-screw the cap

Capping unscrambler:

it's customized according to your caps and droppers.

Company information

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

After-sales service

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality

The Manufacturer shall guarantee the goods are made of Manufacturer's best materials, with first class workmanship, brand new unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from receipt the machine. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

FAQ:

Q:How can I get a Manufacturer automatic filling machine from you?

Just send us inquiry through this web page is ok. I will reply your any question within in 3 hours.

Q:Can your company able to offer 1 years gurantee?

Yes it's no problem for our company. During the warranty, if you need any spare parts, we will delivery it to you in DHL for free.

Q:Do you offer a free set of replacement parts for parts that commonly wear out quickly?

All spare parts are always avaliable for delivery. Above 90% spare parts are made by ourselves. Because we have our own processing center, so we can supply at anytime.

Q:What is the whole production line?Can i connect labeling machine,bottle feeder with filling machine in whole line?

I do not know how many meters of conveyors are involved so can not determine the over-all size of the line with all of its components.

We can help you match pipe and pump to transfer material form raw material tank to filling directly., so it can be totally auatomaticlly.We will design and make a layout plan according to customer's factory floor plan.