Wholesale Price China Chemical Liquid Filling Machine - Hot pot maotai-flavor sauce filling packaging equipment automatic garlic paste filling machine – Ipanda

Wholesale Price China Chemical Liquid Filling Machine - Hot pot maotai-flavor sauce filling packaging equipment automatic garlic paste filling machine – Ipanda Detail:

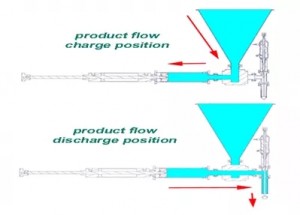

How It Works:

The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper.

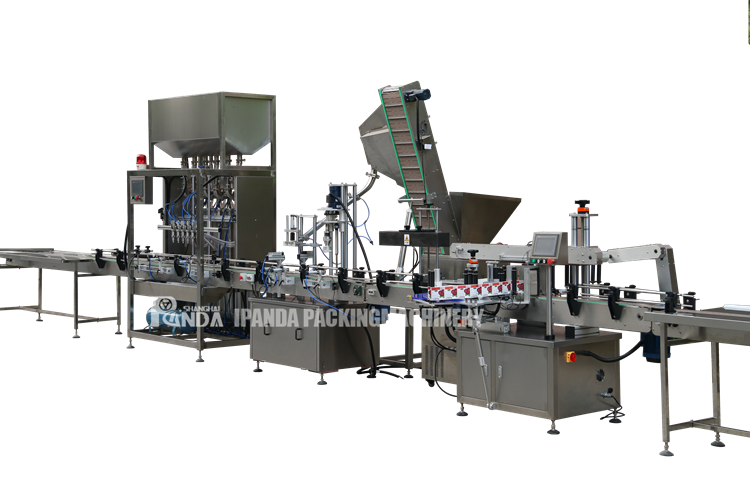

Product Display

Overview

The machine is suitable for the quantitative filling of various kinds of sauces such as tomato sauce, chili sauce, water jam, high concentration and containing pulp or granule beverage, even pure liquid. This machine adopts the principle of upside down piston filling. The piston is driven by the upper cam. The piston and piston cylinder are specially treated. With precision and durability, it is an ideal choice for many food seasoning manufacturers.

Parameter

|

Data sheets |

Details |

| Max filling speed | filling 200ml, 2400~3000 pcs/hour, speed will be different when bottle shape and neck size and the filling material forming and other physical property |

| Applicable bottle diameter size | Φ20 ≤D≤Φ100mm |

| Applicable bottle height size | 30≤H≤300 mm |

| Filling dose | 100~ 1000ml |

| Filling accuracy | ±1% |

| Voltage | AC220V, single phase, 50/60HZ |

| Power | 2.0KW |

| Working pressure | 0.6MP |

| Air consumption | 600L one hour |

| Net weight | 850 Kgs |

| Machine size(L*W*H) | 2000*1200*2250mm |

| Machine direction | from left to right |

| Operation process | put products on conveyer—>Block bottles—> sensor count the empty bottle—> 6 bottle come into the filling station —>lock bottles —>starting filling —> filling finished —> loose Block bottles—> Output bottles |

Features

- 1.Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position

2. Variable speed filling: in filling process, when close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution

3. Convenient adjustment: replacement filling specifications only in touch screen can be changed in parameters, and all filling first change in position, fine-tuning dose it in touch screen adjustment Adopt servo motor to descend

4. Selecting the international famous brand electrical components configuration. Mitsubishi Japan PLC computer, omron photoelectric, Taiwan is produced touch screen, ensure the quality of its outstanding with long-term performance.

Application

Food (olive oil, sesame paste, sauce, tomato paste, chili sauce,butter,honey etc.) Beverage( juice, concentrated juice). Cosmetics (cream, lotion,shampoo, shower gel etc) Daily chemical (dishwashing, toothpaste, shoe polish, moisturizer, lipstick, etc.), chemical (glass adhesive, sealant, white latex, etc.), lubricants, and plaster pastes for special industries The equipment is ideal for filling high-viscosity liquids, pastes, thick sauces, and liquids. we customize machine for different size and shape of bottles.both glass and plastic are OK.

The Machine Details

Adopt SS304 or SUS316L filling nozzles

Filling mouth adopts pneumatic drip-proof device, filling no wire drawing, no dripping;

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

Filling head adopts rotary valve piston pump with the function of anti-draw and anti-dropping.

Company information

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

Product detail pictures:

Related Product Guide:

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for Wholesale Price China Chemical Liquid Filling Machine - Hot pot maotai-flavor sauce filling packaging equipment automatic garlic paste filling machine – Ipanda , The product will supply to all over the world, such as: Orlando, Manchester, Belgium, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!