Short Lead Time for Automatic 6 Nozzles Filling Machine - Liquid Detergent Shampoo Chemical Filling Capping Machine – Ipanda

Short Lead Time for Automatic 6 Nozzles Filling Machine - Liquid Detergent Shampoo Chemical Filling Capping Machine – Ipanda Detail:

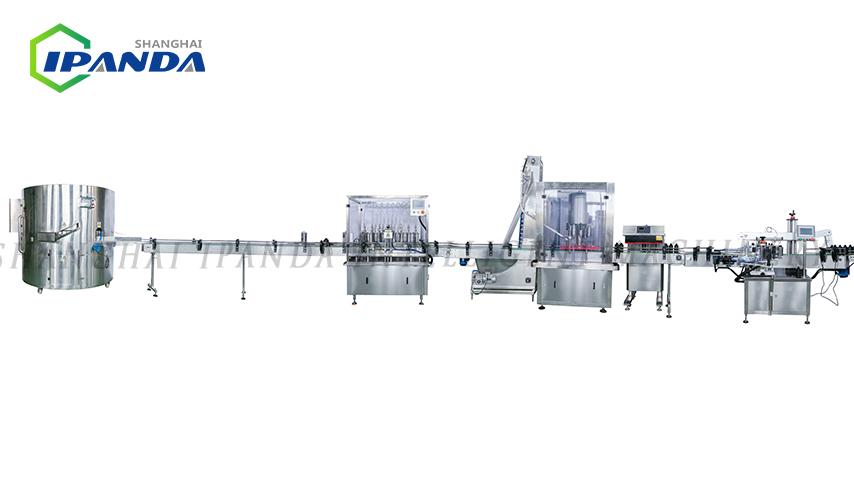

Product Display

Overview

This is our newly developed filling machine . This is a inline piston filling machine for cream and liquid ..It adopts PLC and touch screen control panel for control material . It is characterized by accurate measuring ,advanced structure ,stable operating ,low noise ,large adjusting range ,fast filling speed . It is also suitable for the filling of easy volatilization ,easy bubbly liquid strong corrosive liquid for rubber ,plastic,and high viscosity ,liquid ,semi-liquid . Operators adjust and meter figure in the touch screen control panel , also can adjust metering of each filling head . The external surface of this machine is made of excellent stainless steel . Good appearance , applied to GMP standard .

Automatic bottle uncrambler— Filling machine— Capping machine—Aluminum foil sealing machine — Labeling machine

Parameters

|

Parameter |

Unit |

SHPD Series |

||||

|

Filling heads |

Pcs |

12 |

10 |

8 |

6 |

4 |

|

Filling volume |

ml |

200-1000,500-3000,1000-5000,1500-6000 |

||||

|

Productivity |

bph |

1600-4000 |

1400-3200 |

1200-2600 |

1000-1900 |

720-1300 |

|

Filling tolerance |

% |

<0.5% |

||||

|

Voltage |

V |

According customer country’s standard |

||||

|

Power |

Kw |

1.5 |

1.5 |

1.5 |

1.2 |

1.0 |

|

Gas pressure |

Mpa |

0.55-0.8Mpa |

||||

|

Gas consumption |

M3/min |

0.6 |

0.4 |

1.2 |

1.0 |

0.8 |

Features

1. The use of the world’s famous brand electrical and pneumatic components, low failure rate, stable and reliable performance,long service life;

2. Contact with material are made of stainless steel, tear open outfit is simple, easy to clean, accord with food hygiene requirements;

3. The filling volume and filling speed adjustment is simple, there is the function of no bottle no filling, liquid level automatic control feeding, beautiful appearance;

4. Do not need to change parts, replacement of different specifications of the bottle shape can be changed very fast, high applicability;

5. Filling the mouth with drip tight device, ensure filling without drawing, no dripping.

The Machine Details

Filling part:

ANTI-DROP Filling Nozzles

Equipped with SUS316L long special designed no-drop filling nozzles, which can protect the cylinder on the top being damaged material; Design different size of filling nozzles

SERVO MOTOR Control Filling Volume

SUS304 frame, Round SUS316L PISTONS,TECO servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen

Capping machine and aluminum foil sealing machine

Modular manufacturing,easy to assemble or disassemble,and easy to maintain.Screw the cap at high speed and efficiency is high,Safe and reliable.

Standing Style Incuction Foil sealing machine is widely applied for Fuel additive, medicine bottle, sport bottle, honey jar, medicine bottle ,yogurt bottle, chili sauce and so on.

Capping part

It adopts variable frequency speed regulation, mechanical capping mechanism with complete functions;

The appearance structure of the whole machine is 304 stainless steel, which has good performance, easy operation and beautiful appearance;

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company’s equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of “Good quality , Good service, Good prestige”. We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.

Product detail pictures:

Related Product Guide:

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Short Lead Time for Automatic 6 Nozzles Filling Machine - Liquid Detergent Shampoo Chemical Filling Capping Machine – Ipanda , The product will supply to all over the world, such as: Costa rica, Denver, California, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!