Factory wholesale Lipstick Labeling Machine - Round Bottle Device Pressure Sensitive Sticker Double Side Labeling Machine – Ipanda

Factory wholesale Lipstick Labeling Machine - Round Bottle Device Pressure Sensitive Sticker Double Side Labeling Machine – Ipanda Detail:

Product Display

Overview

Automatic double side adhesive labeling machine is suitable for applying sticker labels on the front and back side of bottles, jars, etc; which are round, flat, oval, rectangular, or square in shape. The labeling speed is also dependent on the stable motion of the product on the conveyor of the equipment,at a relatively higher speed.

Main Technical Parameters

|

Voltage |

AC110/220V 50/60HZ |

|

Labeling Speed |

20-60bottles/min |

|

Labeling Accuracy |

±1mm (depend on the evenness of the plane) |

|

Printer to use air |

5kg/cm2 |

|

Roll Size |

Φ75 mm Φ200 mm |

|

Suitable label size |

15-180mm (W)15-300mm (L) |

|

Dimension |

2000 mm(L)×1000mm(W)×1360mm(H) |

Application

Widely used in medicine, food, beverage and other industries in the cylindrical object or the flat bottle object of the automatic labeling requirements.

Features

1. Applicable to the pharmaceutical, food, cosmetic and other industries, the circumference of the round object and high precision are (double standard) and the fixed point and position on the back label; Can also meet with taper product labeling requirements.

2. The advanced affinity man-machine interface system, easy operation, complete function, has the rich online help function.

3. Unique bottle at three-point position, avoid to linear labeling machine labeling bottle is irregular, and the bottle is not caused by the error of vertical labeling skew, then it let labeling more accurate, beautiful, caresses.

4. Automatic photoelectric detection, it has the function that nothing come from conveyor and no stick label and without label automatic correction or alarm automatic detection function, prevent leakage and waste.

5. The machine structure is simple, compact, easy to operation and maintenance.

Product Details

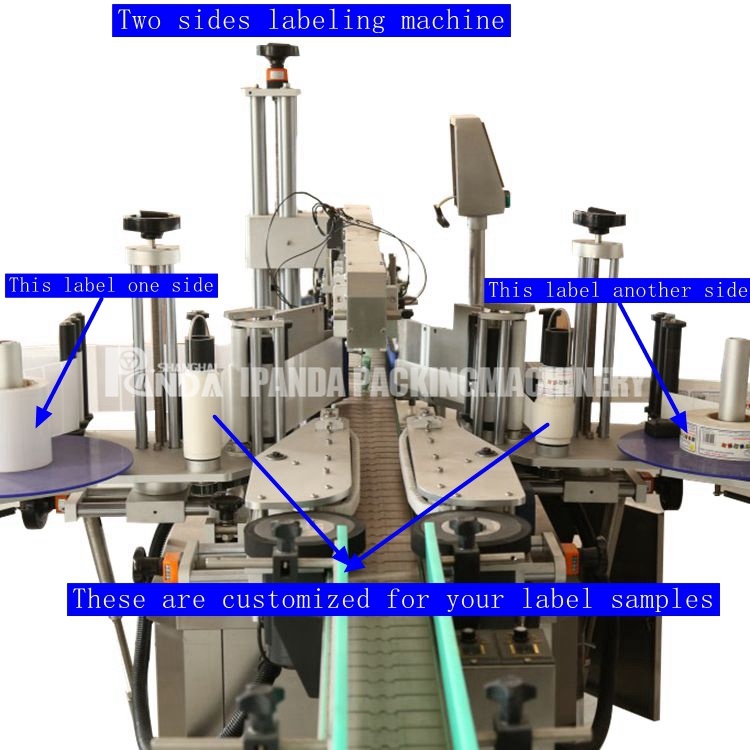

Configuration automatic sub-bottle institutions, automatic separation before the bottle spacing, to ensure follow-up guide bottle, delivery and labeling of the stability;

The two-fold labeling mechanism is configured to ensure the labeling accuracy and the secondary extrusion type labeling for the first time, effectively eliminating bubbles and ensuring the label is tight;

Product detail pictures:

Related Product Guide:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Factory wholesale Lipstick Labeling Machine - Round Bottle Device Pressure Sensitive Sticker Double Side Labeling Machine – Ipanda , The product will supply to all over the world, such as: French, Lahore, El Salvador, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.