Discountable price Mini Water Bottle Packing Machine - Manufacturer Price Fully Automatic Engine/ Gear/ Lube Oil Liquid Filling and Packing Machine in PET Bottle – Ipanda

Discountable price Mini Water Bottle Packing Machine - Manufacturer Price Fully Automatic Engine/ Gear/ Lube Oil Liquid Filling and Packing Machine in PET Bottle – Ipanda Detail:

Product Display

Overview

- Adopt German original SIEMENS (Siemens) PLC control to ensure the performance stability of the system.

- Select imported electricity, pneumatic control components, with stable performance.

- Photoelectric detection system adopts German products, with reliable quality.

- the leading anti-leakage devices ensure that no leakage occurs in the course of production.

- the primary-section delivery adopts variable frequency control,the following process adopts special double dislocation connection.

- High and low double speed filling can avoid the overflow phenomenon, and can significantly increase the production efficiency.

- Single-machine is adapted to multiple varieties, quick and easy adjustment.

- the humanization control system has intelligent protection functions. In case of fault alarm, it will display the reasons for faults to ensure the safety of production process.

- Electrically adjustable capacity system has real-time data tracking function, which allows touching the screen setting to realize the replacement of species, accurately, and conveniently and quickly.

Parameter

| Material | SS304/316L |

| Bottle Material | PET/PE/PP/Glass/Metal |

| Bottle Shape | Round/Square/Unique Square |

| Capping Method | Screw cap, Press cap, Twisting Cap |

| Bottle Components | Rapid replacement without tools, such as star wheels for bottle infeed and outfeed, and bottleneck clamps |

| Control System | PLC and touch screen |

| Filing Precision | ±1% |

| Filling material | Oil,cooking oil,engine oil etc. |

| Power Supply | 220V/380V 50/60HZ |

| Filling Speed | 1000-6000 bottles per hour(Customized) |

| Filling Nozzles | 2/4/6/8/10/12(Customized) |

| Dosing System | Piston pump |

| Filling Capacity | 100-5000ml(Customized) |

| Air Supplier | 0.6-0.8MPa |

| Power | 2.0KW |

| Weight | 500kg(Customized) |

| Dimension(mm) | 2500*1400*1900mm (Customized) |

Features

1.Adopt German original SIEMENS (Siemens) PLC control to ensure the performance stability of the system.

2.Select imported electricity, pneumatic control components, with stable performance.

3.Photoelectric detection system adopts German products, with reliable quality.

4.The leading anti-leakage devices ensure that no leakage occurs in the course of production.

5.The primary-section delivery adopts variable frequency control,the following process adopts special double dislocation connection.

6.High and low double speed filling can avoid the overflow phenomenon, and can significantly increase the production efficiency.

7.Single-machine is adapted to multiple varieties, quick and easy adjustment.

Application

It is used for automatic filling of various liquids into bottles.Such as oil,cooking oil,sunflower oil,vegetable oil,engine oil,car oil,motor oil.

The Machine Details

Piston cylinder

According to customer production capacity requirements could make different size cylinder

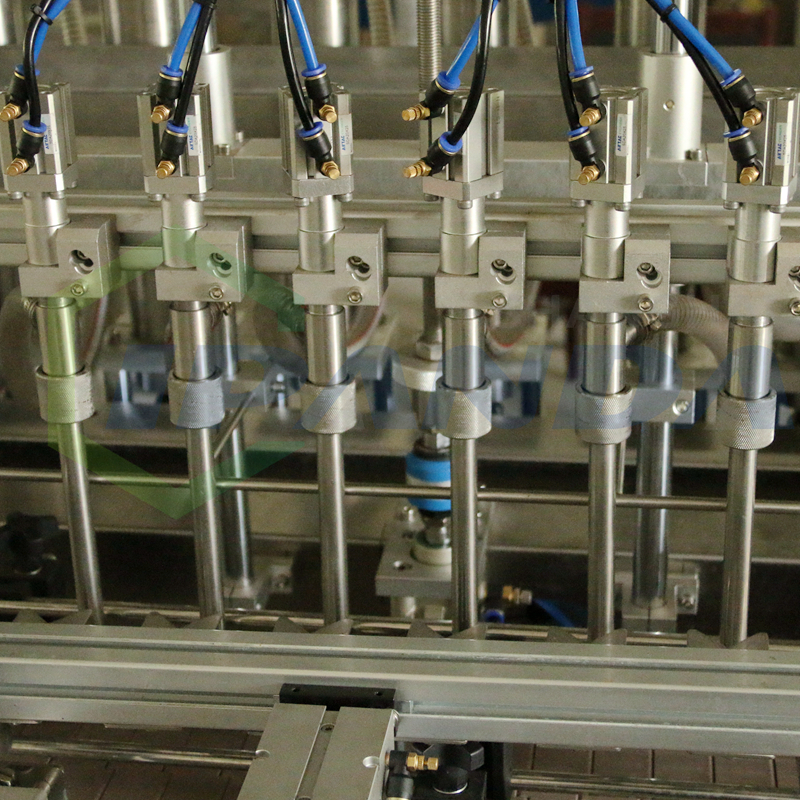

Filling system

Filling nozzle adopt bottle mouth diameter custom made,

Filling nozzle are with suck-back function, to avoid leakage suitable material oil, water, syrups, and some other material with good fluidity.

Oil use tree way valve

1. Connecting among tank, rotaty valve, position tank all with fast remove clip.

2. Adopt oil use three way valve, which is suitable for oil, water, and material with good fuidity, the valve is special designed for oil without leakage, ensure high accuracy.

Adopt strong applicablity

No need to change parts,can quickly adjust and change bottles of different shapes and specification

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Photoelectric sensor and pneumatic door coordinate control ,lack bottle ,pour bottle all has automatic protection .

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

Product detail pictures:

Related Product Guide:

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Discountable price Mini Water Bottle Packing Machine - Manufacturer Price Fully Automatic Engine/ Gear/ Lube Oil Liquid Filling and Packing Machine in PET Bottle – Ipanda , The product will supply to all over the world, such as: Gabon, Kuwait, Benin, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.