China Supplier Small Bottle Filler - Automatic honey jar filling and capping machine for plastic bottle – Ipanda

China Supplier Small Bottle Filler - Automatic honey jar filling and capping machine for plastic bottle – Ipanda Detail:

Product Display

Overview

The machine is suitable for the quantitative filling of various kinds of sauces such as tomato sauce, chili sauce, water jam, high concentration and containing pulp or granule beverage, even pure liquid. This machine adopts the principle of upside down piston filling. The piston is driven by the upper cam. The piston and piston cylinder are specially treated. With precision and durability, it is an ideal choice for many food seasoning manufacturers.

Parameter

| Filling speed | Can be customized | Net weight | 600KG |

| Bottle diameter size | Φ20 ≤D≤Φ100mm

(can be customized) |

Voltage | AC220V, 380V, 50/60HZ |

| Bottle height size | 30≤H≤300 mm

(can be customized) |

Power | 2KW |

| Filling accuracy | ±1% | Working pressure | 0.6-0.8Pa |

| Air consumption | 700L one hour | Machine size(L*W*H) | 2100*1560*1650mm |

Features

1. The flow control devices of each filling head are independent of each other, precision adjustment is very convenient.

2. The material of the machine material contact part can use the food grade material according to the products feature, in line with the GMP standard.

3. With regular filling, no bottle no filling, filling quantity/production counting function etc features.

4. Convenient maintenance,no need any special tools.

5. Using drip tight filling head,no leaking.

6. Photoelectric Sensor, Mechatronics Filling Adjustment System,Material Level Control Feeding System

7.Stainless Steel Frame,Plexiglass as Security Cover

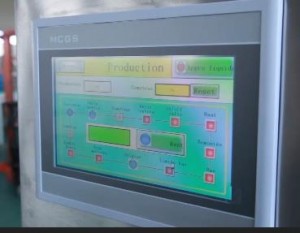

8. Control System: PLC/Electronic-Pneumatic Controlled

9. Capaity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

Our Advantages

High flexibility:

A. able to fill different product like liquid, and dense liquid like cream, paste as well.

B. different numbers of filling head to meet different production capacity requirement.

C. Fit for bottles in different sizes, need only 5-10 min to change one size to another.

High quality and safety level.

A. main cabinet separately placed far above behind the filling nozzles,no worries of electrical shock caused by falling bottles.

B. full 304 stainless steel to meet food cleanness standard.

Application

Food (olive oil, sesame paste, sauce, tomato paste, chili sauce,butter,honey etc.) Beverage( juice, concentrated juice). Cosmetics (cream, lotion,shampoo, shower gel etc) Daily chemical (dishwashing, toothpaste, shoe polish, moisturizer, lipstick, etc.), chemical (glass adhesive, sealant, white latex, etc.), lubricants, and plaster pastes for special industries The equipment is ideal for filling high-viscosity liquids, pastes, thick sauces, and liquids. we customize machine for different size and shape of bottles.both glass and plastic are OK.

The Machine Details

Adopt SS304 or SUS316L filling nozzles

Accurate measurement, no splashing, no overflow

Adopts piston pump filling, high precision; The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

Adopt strong applicablity

No need to change parts,can quickly adjust and change bottles of different shapes and specification

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Filling head adopts rotary valve piston pump with the function of anti-draw and anti-dropping.

Company information

Company profile

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging

FAQ

Q1. What’s the payment terms and trade terms for new customers?

A1: Payment terms: T/T, L/C, D/P, etc.

Trade terms: EXW, FOB, CIF.CFR etc.

Q2:What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A2:Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

Q3: What’s the Minimum Order Quantity and warranty?

A3: MOQ: 1 set

Warranty: We offer you high quality machines with 12 months guarantee and offer technical support on time

Q4: Do you provide customized service?

A4: Yes, We have professional engineers whom have good experience in this industry for many years, they offer proposals include design machines, complete lines base on your project capacity, configuration requests, and others, make sure fulfill customer needs in market.

Q5.:Are you provide product metal parts and provide us technical guidance?

A5:Wearing parts,for example, motor belt,Disassembly tool(free) are what we could provide.And we can give you technical guidance.

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very best excellent and aggressive portable digital products for China Supplier Small Bottle Filler - Automatic honey jar filling and capping machine for plastic bottle – Ipanda , The product will supply to all over the world, such as: Nigeria, Slovakia, Leicester, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.