China OEM Automatic Liquid Packaging Machine - Pharmaceutical Antibiotic Bottle Vial Washing Sterilization Filling Machine Production Line – Ipanda

China OEM Automatic Liquid Packaging Machine - Pharmaceutical Antibiotic Bottle Vial Washing Sterilization Filling Machine Production Line – Ipanda Detail:

Product Display

Overview

The vial filling production line is composed of ultrasonic bottle washing machine, dryer sterilizer, filling stoppering machine, and capping machine. It can complete spraying water, ultrasonic cleaning, flushing of inner and outer wall of bottle, preheating, drying and sterilization, heat source removing, cooling, bottle unscrambling, (nitrogen pre-filling), filling, (nitrogen post-filling), stopper unscrambling, stopper pressing, cap unscrambling, capping and other complex functions, realizing automatic production of the whole process. Each machine can be used separately, or in linkage line. The whole line is mainly used for filling of vial liquid injections and freeze-dried powder injections in pharmaceutical factories, it can also be applied to production of antibiotics, bio-pharmaceuticals, chemical pharmaceuticals, blood products etc.

Parameter

| Model | SHPD4 | SHPD6 | SHPD8 | SHPD10 | SHPD12 | SHPD20 | SHPD24 |

| Applicable specifications | 2~30ml vial bottles | ||||||

| Filling heads | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Production capacity | 50-100bts/min | 80-150bts/min | 100-200bts/min | 150-300bts/min | 200-400bts/min | 250-500bts/min | 300-600bts/min |

| Stoppling qualification rate | >=99% | ||||||

| Laminar air cleanliness | 100 grade | ||||||

| Vacuum pumping speed | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h | 120m3/h |

| Power consumption | 5kw | ||||||

| Power supply | 220V/380V 50Hz | ||||||

Machine configuration

|

Frame |

SUS304 Stainless steel |

|

Parts in contact with liquid |

SUS316L Stainless steel |

|

Electrical parts |

|

|

Pneumatic part |

|

Features

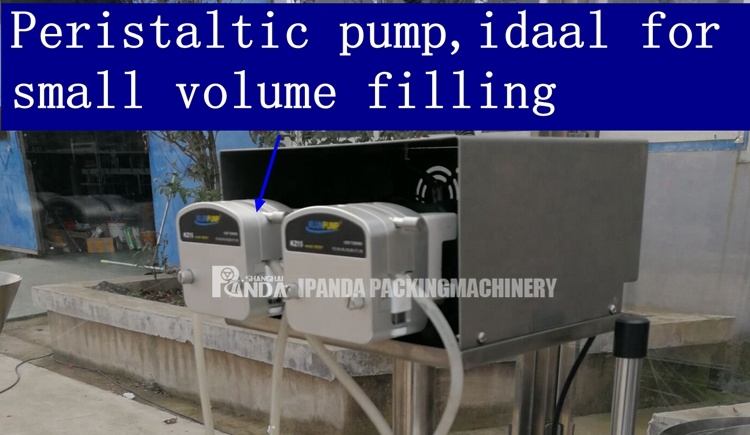

- Peristaltic pump or high precision peristaltic pump filling, filling speed is high and filling error is small.

2. Groove cam device positions bottles precisely. Running is stable, change part is east to change.

3. Button control panel is easy to operate and it has high automation degree.

4. Falling bottle auto rejected in the turntable, no bottle, no filling; machine auto stops when no stopper; auto alarms when

insufficient stopper.

5. Equip with auto counting function.

6. Certified, standard electric installation, safety guarantee on operation.

7. Optional acrylic glass protection hood and 100-class laminar flow.

8. Optional pre-filling and after-filling nitrogen filling.

9. The whole machine is designed according to GMP requirements.

Working Process

The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided.

The Machine Details

1)This is filling pipes, it is high quality imported pipes.There are the valves on the pipe, it will suck liquid back after once filling. So filling nozzles will not leakage.

2) The multi roller structure of our peristaltic pump further improves the stability and non impact of filling and makes the liquid filling stable and not easy to blister. It is especially suitable for filling the liquid with high requirement.

3)This is aluminum Cap sealing head. It has three sealing roller. It will sealing Cap from four sides, so the sealed Cap is very tighten and beautiful. It will not damage Cap or leakage Cap.

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for China OEM Automatic Liquid Packaging Machine - Pharmaceutical Antibiotic Bottle Vial Washing Sterilization Filling Machine Production Line – Ipanda , The product will supply to all over the world, such as: British, Cyprus, Belgium, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.