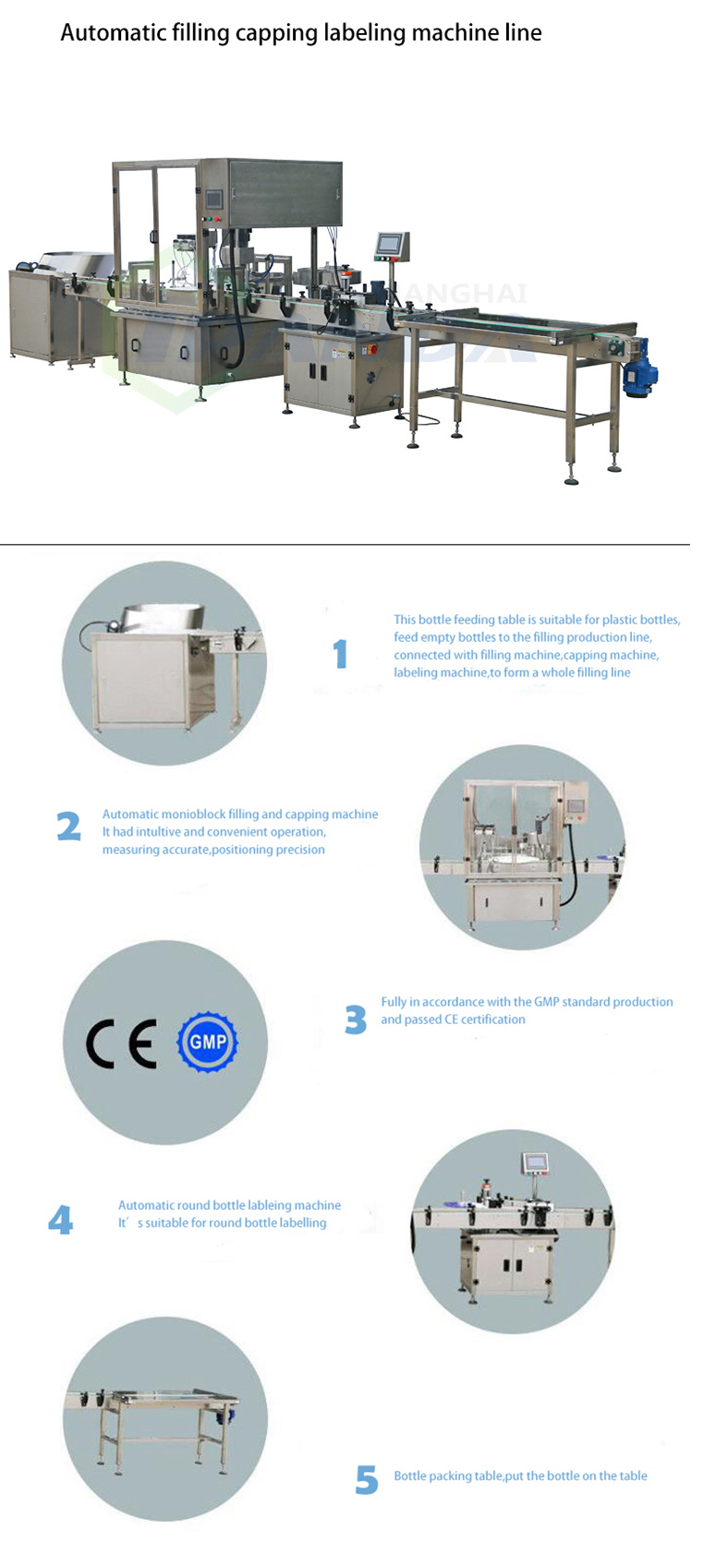

Automatic Electronic Liquid Bottle Filling Capping And Labeling Machine Line

|

Applicable specifications |

1ml-200mml or customized |

|

Production capacity |

30-40 Bottle/min or customized |

|

Filling accuracy |

≤±1% |

|

Power supply |

220V/50Hz |

|

Rotating (rolling) cover rate |

≥99% |

|

Power |

2.0 kw |

|

Machine net weight |

650 kg |

|

Dimensions |

2440*1700*1800mm |

1. It can be equipped with a protecting cover and a checking-drop installation according to client’ s requirement;

2. It has the advantage of high-level automation degree, high-rate of finished products, good adaptability and stability which is popular among users;

3. The advantage of the machine is easy operating and saving labor and room;

4. No bottle, no filling. This machine is simple operation, saving merits of human, not consumption field, etc;

The detail pictures:

We adopt SS304 Filling nozzles and food grade slicone tube

Cap sorter is customized for your cap

It unscramble the caps and convey to capping part of the machine.

Inserting dropper-putting cap

Adopt magnetic torque screwing capping

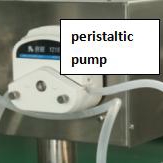

Adopt Peristaltic pump,It’s suitable for fruid liquid filling.

Adopt PLC control,touch bottle operation, simple and convenient operation;

Shanghai Ipanda Intelligent Machinery Co., Ltd. is a comprehensive enterprise specialized in the design, manufacture, R&D, trade of filling equipment and packaging equipment.Our R&D and manufacture team has more than 10 years of experience in the filling industry. Our factory covers an area of 5000 square meters,now it has a second factory as a showroom, which includes a complete set of production lines for packaging equipment in the daily chemical, pharmaceutical, petrochemical, and food industries.

Click this picture to see our factory information