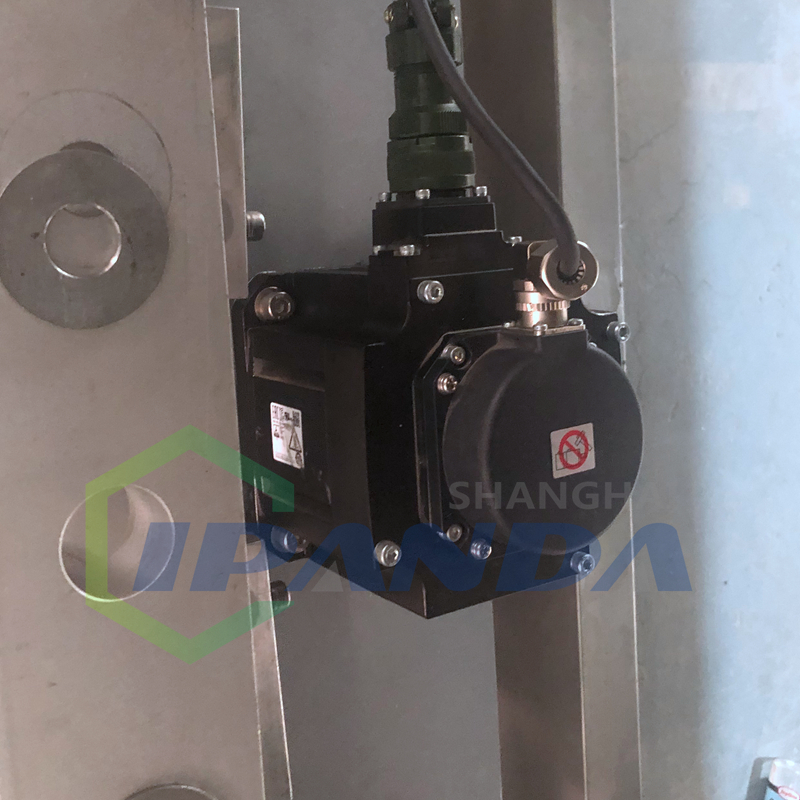

1. Servo motor oil and water protection

A: Servo motors can be used in places that will be attacked by water or oil droplets, but it is not completely waterproof or oil-proof. Therefore, Servomotors should not be placed or used in water or oil-invaded environments.

B: If the servo motor is connected to a reduction gear, oil seal should be used when using the servo motor to prevent the oil of the reduction gear from entering the servo motor

C: The cable of the servo motor should not be immersed in oil or water.

2. Servo motor cable → reduce stress

A: Make sure that the cables are not subjected to moments or vertical loads due to external bending forces or their own weight, especially at cable exits or connections.

B: In the case of the servo motor moving, the cable (that is, the one equipped with the motor) should be firmly fixed to a stationary part (opposite the motor), and should be extended with an additional cable installed in the cable holder it, so that the bending stress can be minimized.

C: The elbow radius of the cable should be as large as possible.

3. The allowable shaft end load of the servo motor

A: Make sure that the radial and axial loads added to the servo motor shaft during installation and operation are controlled within the specified values of each model.

B: Take extra care when installing a rigid coupling, especially if excessive bending loads may cause damage or wear to the shaft end and bearings

C: It is better to use a flexible coupling so that the radial load is lower than the allowable value, which is specially designed for the servo motor with high mechanical strength.

D: For the allowable shaft load, refer to the “Permissible Shaft Load Table” (Instruction Manual).

Fourth, the servo motor installation attention

A: When installing/removing the coupling parts to the shaft end of the servo motor, do not hit the shaft end directly with a hammer. (The hammer hits the shaft end directly, and the encoder on the other end of the servo motor shaft will be damaged)

B: Do your best to align the shaft end to the best condition (misalignment may cause vibration or bearing damage).

First, let’s take a look at the advantages of servo motors compared to other motors (such as stepper motors):

1. Accuracy: closed-loop control of position, speed and torque is realized; the problem of stepper motor out-of-step is overcome;

2. Speed: good high-speed performance, generally rated speed can reach 2000~3000 rpm;

3. Adaptability: strong anti-overload capability, able to withstand loads three times the rated torque, especially suitable for occasions with instantaneous load fluctuations and fast start requirements;

4. Stable: The low-speed operation is stable, and the stepping operation phenomenon similar to the stepping motor will not occur during low-speed operation. Suitable for occasions with high-speed response requirements;

5. Timeliness: The dynamic response time of motor acceleration and deceleration is short, generally within tens of milliseconds;

6. Comfort: heat and noise are significantly reduced.

Post time: Aug-17-2022