Automatic Edible Cooking Vegetable Soybean Peanut Oil Filling Capping Labeling Machine

This filling machine adopts the PLC and the weighing feedback system that makes a higher filling precision. All operations complete on the touching screen. It is reliable, stable, widely used for 20L oil filling.

| Filling speed | 2000-3000Bottles/hour(customized) |

| Filling range | 1000ml-5000ml(customized) |

| Filling precision | ±1% |

| Power | 220v/50hz |

| Air pressure | 6-7kg/cm2 |

| Dimension | 2500*1400*2200mm |

1. This machine is suitable for filling aqueous solutions and cream products, particularly for high viscosity materials (such as cosmetics, seed coating agent, motor lubricating oil, suspending agent etc.) the effect is obvious.

2. Using PLC programmable control, with touch screen and man-machine interface system; automatic bottle feeding, automatic filling, automatic send bottle out; driven by a servo motor, double screw drive, control the movement of the piston rod to ensure the stability of the filling, filling precision higher.

3.Used double liquid box and is provided with a filter plate, mechanical three-way easy to clean and replace the material more convenient. It can be with the capping machine, labeling machine supporting the formation of whole production line.

4.It integrates light, machine, electricity and gas into one body. Is an easy to operate.

It is used for automatic filling of various liquids into bottles.Such as oil,cooking oil,sunflower oil,vegetable oil,engine oil,car oil,motor oil.

Piston cylinder

According to customer production capacity requirements could make different size cylinder

Filling system

Filling nozzle adopt bottle mouth diameter custom made,

Filling nozzle are with suck-back function, to avoid leakage suitable material oil, water, syrups, and some other material with good fluidity.

Oil use tree way valve

1. Connecting among tank, rotaty valve, position tank all with fast remove clip.

2. Adopt oil use three way valve, which is suitable for oil, water, and material with good fuidity, the valve is special designed for oil without leakage, ensure high accuracy.

Adopt strong applicablity

No need to change parts,can quickly adjust and change bottles of different shapes and specification

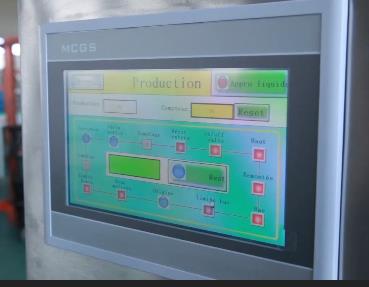

Adopt Touch screen and PLC Control

Easy adjusted filling speed/volume

no bottle and no filling function

level control and feeding.

Photoelectric sensor and pneumatic door coordinate control ,lack bottle ,pour bottle all has automatic protection .

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

- Dedication to Research & Development

- Experienced Management

- Better understanding of Customer requirement

- One Stop solution provider with Broad Range Offering

- We can supply OEM&ODM design

- Continuous Improvement with Innovation

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide new one or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it at your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer's best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be covered by buyer's side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging.

FAQ

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,we can tell you their contact imformation,you can go to vist their factory.And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city.Contact our sales people you can get video of our reference running machine

Q2: Do you provide customized service

A2: We can design the machines according your requirements(materil ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q3: What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 1 year guarantee and supply life-long technical support.