Semi-Automatic Milk 15L Bag in Box Filling Machine

This bag in box filling machine is a small smart dosing machine with high filling precision. It includes filling and capping at one station. It, s easy to set up and adjust the filling volume. It, s widely used in bag in box filling of all kinds of liquid and semi-liquid like wine, edible oil, fruit juice, additives, milk, syrup, maple syrup, tomato sauce, fruit jam, egg paste, liquid fertilizer, soysauce etc.

Easy operate, smart BIB filling machine

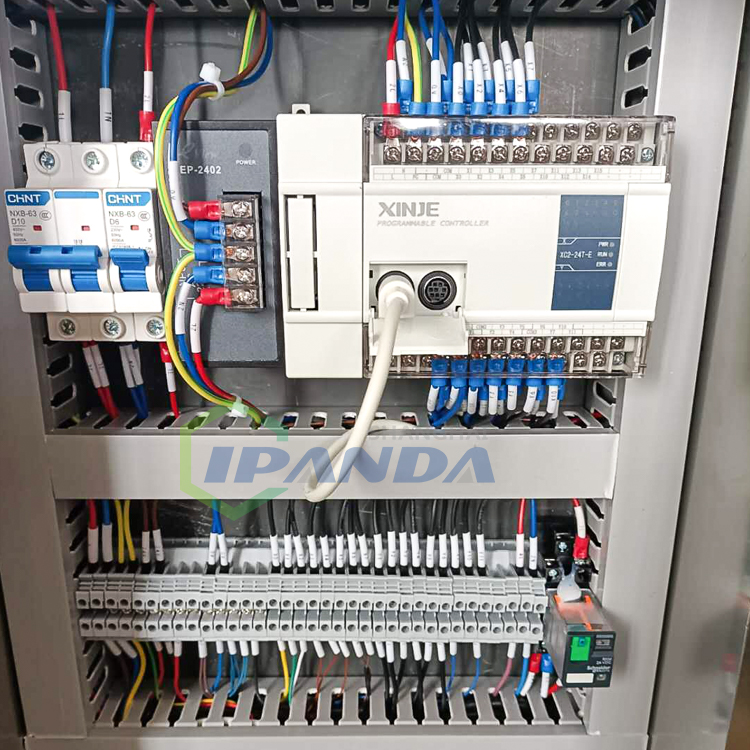

This machine consists of stainless steel frame, electric control system, quantitative filling system, vacuum pumping system,capping system.

|

Technical Parameter |

|

|

Model |

Bag In Box Filling Machine |

|

Filling speed |

4-5 bags/min ( when filling 20L) |

|

Filling range |

1-25L( customization) |

|

Filling accuracy |

≤±1% |

|

Air pressure |

6-8bar |

|

Total power |

150W |

|

Power supply |

AC 220V 50/60Hz |

|

Mahcine size |

L1005*W1315*H1795mm |

|

Net weight |

200KG |

It can be widely used in bag-in-box filling applications for such liquid materials as water,wine, edible oil, fruit juice, additives, milk, syrup, alcoholic beverages and concentrated seasonings.

1). The machine is mainly made of quality stainless steel; the parts contact the material is made of 304# stainless steel and food grade plastic tubes and comply with hygienic standards for food;

2).It can fullfill accurate filling and capping at one operating position.

3). The machine uses flow meter for filling which is with high filling precise.

4). All its pneumatic and electric parts are from world famouse brand which are good quality.

5). can achieve vacuum pumping before they are filled, thereby helping extend the shelf life of the product.

6) Can add nitrogen function according to clients requirement.

alcoholic beverages and concentrated seasonings.suitable for all kinds of bags and caps.

Adopt PLC control and touch screen operation, the display is intuitive and easy to operate.

ABOUT

COMPANY OVERVIEW

Growing Your Skills

Providing Best Talent Solution For

We Have More Than 20+ Years Practical Experience in Agency

- Dedication to Research & Development

- Experienced Management

- Better understanding of Customer requirement

- One Stop solution provider with Broad Range Offering

- We can supply OEM&ODM design

- Continuous Improvement with Innovation

Q1: What is your company's main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.