Factory Direct Sale Chemical Liquid Bottle Filling Capping Machine

This machine have been widely used in manufacturing,chemical,food,beverage and other industries.It is especially designed for high viscosity liquid Easily controlled by computer (PLC), touch screen control panel . It is characterized by its totally close from ,submerged filling ,high measurement accuracy , compact and perfect feature ,liquid cylinder and conduits disassemble and clean . It may also suited various figure containers . We utilize high-quality stainless steel frames , international famous brand electrical components , the machine is applied to GMP standard requirement.

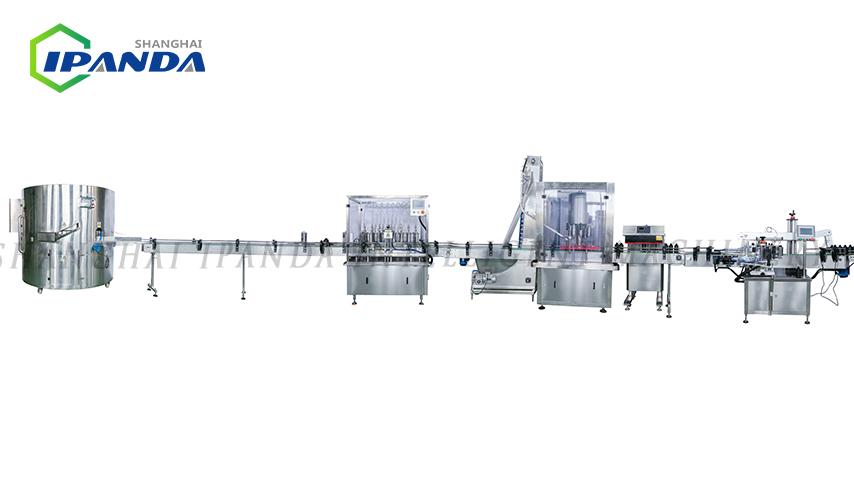

Automatic bottle uncrambler--- Filling machine--- Capping machine---Aluminum foil sealing machine --- Labeling machine

|

Parameter |

Unit |

SHPD Series |

||||

|

Filling heads |

Pcs |

12 |

10 |

8 |

6 |

4 |

|

Filling volume |

ml |

200-1000,500-3000,1000-5000,1500-6000 |

||||

|

Productivity |

bph |

1600-4000 |

1400-3200 |

1200-2600 |

1000-1900 |

720-1300 |

|

Filling tolerance |

% |

<0.5% |

||||

|

Voltage |

V |

According customer country's standard |

||||

|

Power |

Kw |

1.5 |

1.5 |

1.5 |

1.2 |

1.0 |

|

Gas pressure |

Mpa |

0.55-0.8Mpa |

||||

|

Gas consumption |

M3/min |

0.6 |

0.4 |

1.2 |

1.0 |

0.8 |

1. Adopts positive displacement plunger pump for filling, high precision, large range of adjusting dosage, can regulate filling amount of all the pump body as a whole, also can adjust a single pump slightly, quick and convenient.

2. Plunger pump filling system has features of no adsorbing drugs, good chemical stability, high temperature resistance, corrosion resistance, abrasion resistance, long service life, has unique advantages when fill some corrosive liquid.

3.Machine can be customized with 4/6/8/12/14/etc filling heads according to customer's production capacity.

4. Used for various viscosity liquid filling, frequency control,

5. Machine body is made of 304 stainless steel, full compliance with GMP standard.

Filling part:

ANTI-DROP Filling Nozzles

Equipped with SUS316L long special designed no-drop filling nozzles, which can protect the cylinder on the top being damaged material; Design different size of filling nozzles

SERVO MOTOR Control Filling Volume

SUS304 frame, Round SUS316L PISTONS,TECO servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen

Capping machine and aluminum foil sealing machine

Modular manufacturing,easy to assemble or disassemble,and easy to maintain.Screw the cap at high speed and efficiency is high,Safe and reliable.

Standing Style Incuction Foil sealing machine is widely applied for Fuel additive, medicine bottle, sport bottle, honey jar, medicine bottle ,yogurt bottle, chili sauce and so on.

Capping part

It adopts variable frequency speed regulation, mechanical capping mechanism with complete functions;

The appearance structure of the whole machine is 304 stainless steel, which has good performance, easy operation and beautiful appearance;

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company's equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of "Good quality , Good service, Good prestige". We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.