Eyedrop/e-liquid filling capping machine tincture filling machine auto

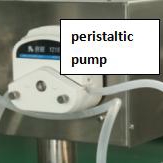

Filling part of the machine can be used 316L stainless steel peristaltic pump pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. It is suitable for products of liquid such as essential oil, eye drop,nail polish etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent etc.The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements.

|

Main parameter of the machine |

|||

| Name | Filling capping machine | Filling volume | 5-250ml,can be customized |

| Net weight | 550KG | Filling heads | 1-4 heads,can be customized |

| Bottle diameter | Can be customized | Filling speed | 1000-2000BPH,can be customized |

| Bottle height | Can be customized | Voltage | 220V,380V ,50/60GZ |

| Filling accuracy | ±1ml | Power | 1.2KW |

| Bottle material | Glass ,plastic bottle | Working pressure | 0.6-0.8MP |

| Filling material | Eye drop,e-liquid,cbd oil | Air consumption | 700L per hour |

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

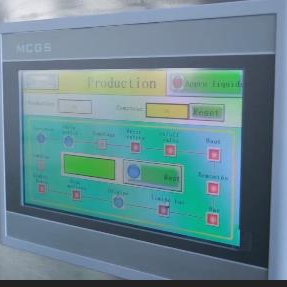

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

The material will be pumped through the reciprocating piston filling machine under the action of the cylinder. The cylinder of the pumping stroke is adjusted by a signal valve to adjust the required filling volume to achieve precise filling results.

The detail pictures:

We adopt SS304 Filling nozzles and food grade slicone tube

Cap sorter is customized for your cap

It unscramble the caps and convey to capping part of the machine.

Inserting dropper-putting cap

Adopt magnetic torque screwing capping

Adopt Peristaltic pump,It’s suitable for fruid liquid filling.

Adopt PLC control,touch bottle operation, simple and convenient operation;

1.Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.