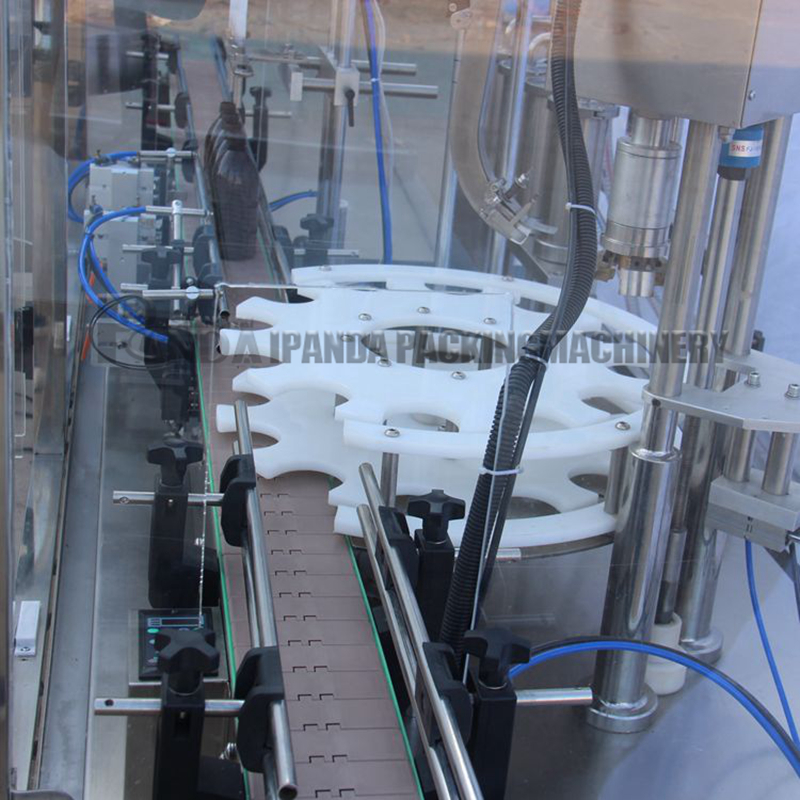

Automatic Syrup Oral Liquid Filling Capping Machine

This machine is mainly used for the filling production line of reagents and other small-dose products. It can realize automatic feeding, high-precision filling, positioning and capping, high-speed capping, and automatic labeling. This machine adopts mechanical rotation to ensure accurate and stable operation, low noise, low loss, and no air source pollution. The whole machine is made of stainless steel 304, which meets GMP requirements.

|

Applicable specifications |

30ml-100mml customize |

|

Production capacity |

30 bottles/min (four heads) |

|

Filling accuracy |

≤±2% |

|

Power supply |

220V/50Hz |

|

Rotating (rolling) cover rate |

≥99% |

|

Power |

2.0 kw |

|

Machine net weight |

650 kg |

|

Dimensions |

2440*1700*1800mm (four-head size) |

1. The bottle entering mode can be in different scheme based on the user’s requirement and bottle shape feature.

2. Adopting 316L stainless steel piston cylinder, and ceramic plunger type cylinder or designated method by user for precision filling, the filling accuracy is ±0.5~1%

3. The function of automatic alarm and stop when filling needles deviate from bottle neck.

4. The unique inlet and outlet check valve and the precision machining to ensure not dropping when filling. The filling needle will move up and down or submersible filling, to prevent liquid bubbling or splashing.

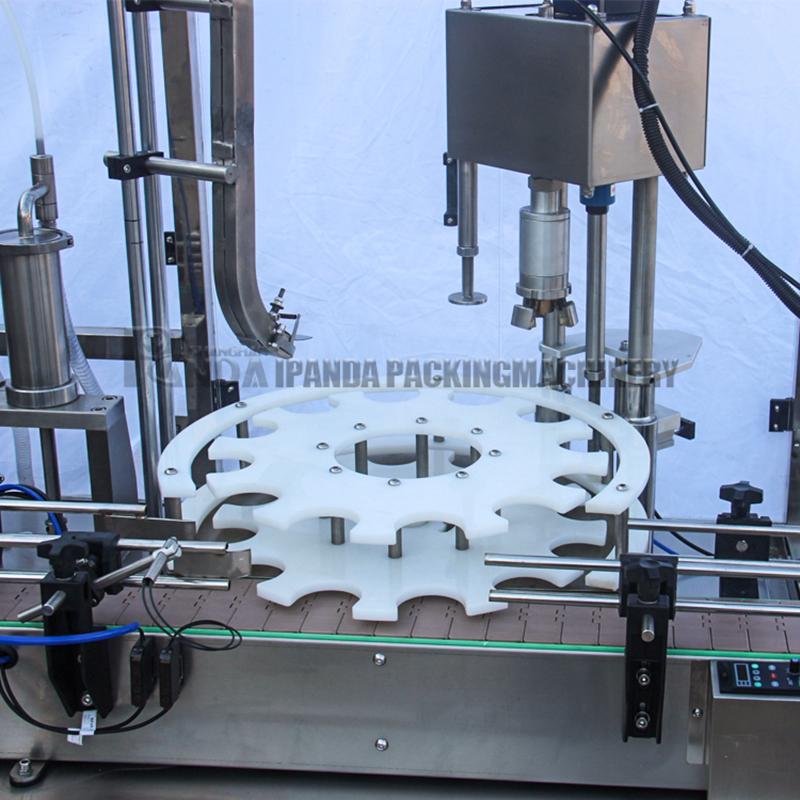

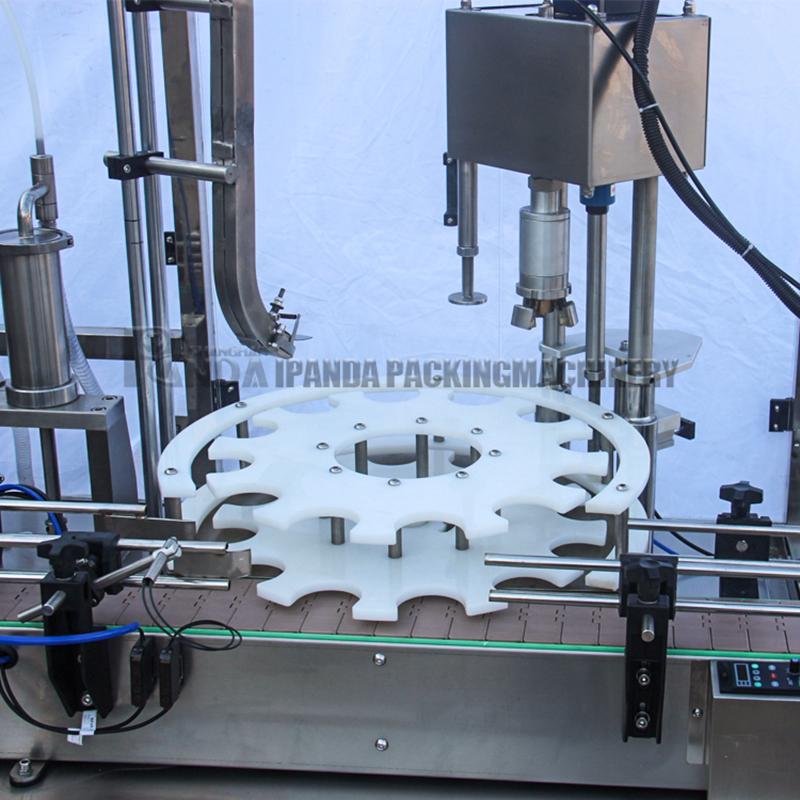

5. The specially designed lid and lid feeding matched automatic precisely up with capping, accurately complete each mechanical motion cycle, such as crabbing lid, capping, and others, the whole process in unison, stably and reliably, without dropping lid.

6. The whole production line of intelligent control has the function of chain control for upstream and downstream working equipment.

7. The surface of main parts of the whole production line is made of SUS 304 stainless steel, hardness of anodized aluminum alloy, non-toxic polymeric materials, etc. which comply with GMP rules.

The syrup filling and capping machine is mainly used in the food, pharmacy and chemical industry and suitable for filling different kinds of round bottles and bottle in irregular shape with metal or plastic caps and filling for the liquid like the syrup, oral liquid, honey etc.

Adopt SS304 or SUS316 filling nozzles

No-drip filing nozzles, which can protect the cylinder on the top being damaged by material.Easy to operate, no bottle no filling, auto orientation detection.

Capping part

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps