Automatic Small Production Line Cosmetic Nail Polish Filling Capping Machine

This machine is suitable for small dose liquid packaging production line in cosmetics,daily chemical and pharmaceutical industries etc, Can automaticlly complete filling, plug, screw cap,rolling cap, capping, bottling and other process.The whole machine is made of SUS304 stainless steel and the same grade aluminum alloy treated by positive grade, never rust, accord with GMP standard.

The equipment is ideal for filling small volume bottles, we customize machine for different size and shape of bottles, both glass and plastic are OK. It is widely used in Cosmetics (essential oil, perfume, nail polish, eye drop etc) chemical (glass adhesive, sealant, white latex, etc.) industries etc.

| Filling volume | 10ml~250ml |

| Suitable diameter of bottles | Ф15mm~Ф100mm |

| Measure precision | ±0.01% (≤200ml) |

| Production capacity | ≤2000 bottles/hour |

| Air pressure | 0.6~0.8MPa |

| Amount of Air-consuming | 200 l/min |

| Power supply | AC 220V/50Hz (Customized) |

| Power | 2.5Kw |

| Machine weight | About 800Kg |

| Machine dimension (L×W×H) | 2000mm×2000mm×2100mm |

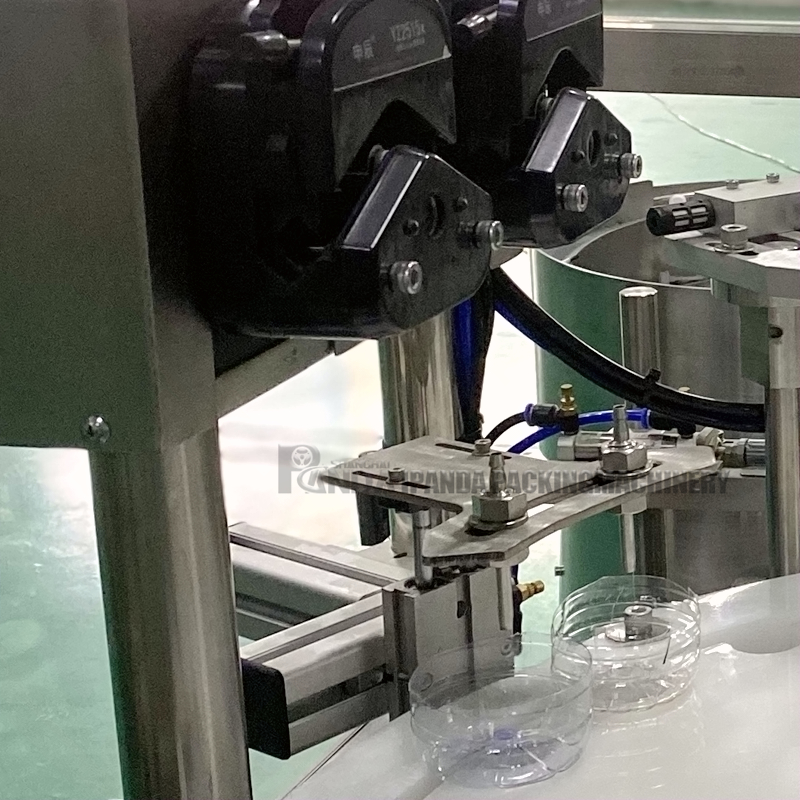

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage.

2. Peristaltic pump filling, measuring precision, convenient manipulation.

3. Filling system has function of suck back, avoid liquid leak through.

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping.

5. Filling nozzle is made by 316 stainless steel, machine body is made by 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

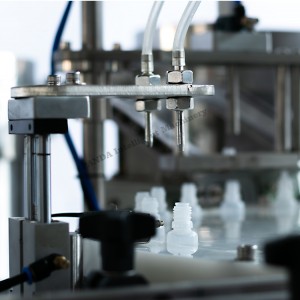

Filling part:

Adopt SS304 filling nozzles and food grade Silicone tube.It's meet CE Standard.Filling nozzle dive into bottle to fill and rise slowly to prevent foaming.

Peristaltic pump filling, measuring precision, convenient manipulation;

Capping part: Put the brush plug-- Put the cap-Screw cap

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality:

The Manufacturer shall guarantee the goods are made of Manufacturer's best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer's side (round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging. back, avoid liquid leak through;

1. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

2. Adding plug device can choose fixed mold or mechanical vacuum mold;

3. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

4. Integrated with mechanical, electrical & pneumatic system, the monoblock design is less space-taking, reliable & economical, with flexible adaptability and high automation, espcially good for OEM, ODM products & not big scale auto production;

FAQ

Q1: What is your company's main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q6:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q7:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.