Automatic small bottle perfume factory price filling capping machine

This machine is suitable for small dose liquid packaging production line in cosmetics,daily chemical and pharmaceutical industries etc, Can automaticlly complete filling, plug, screw cap,rolling cap, capping, bottling and other process.The whole machine is made of SUS304 stainless steel and the same grade aluminum alloy treated by positive grade, never rust, accord with GMP standard.

| Applied Bottle | 5-200ml customized |

| Productive Capacity | 30-100pcs/min |

| Filling Precision | 0-1% |

| Qualified stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V,50Hz/220V,50Hz (customized) |

| Power | 2.5KW |

| Net Weight | 600KG |

| Dimension | 2100(L)*1200(W)*1850(H)mm |

1)No bottle, no filling / no plugging / no capping.

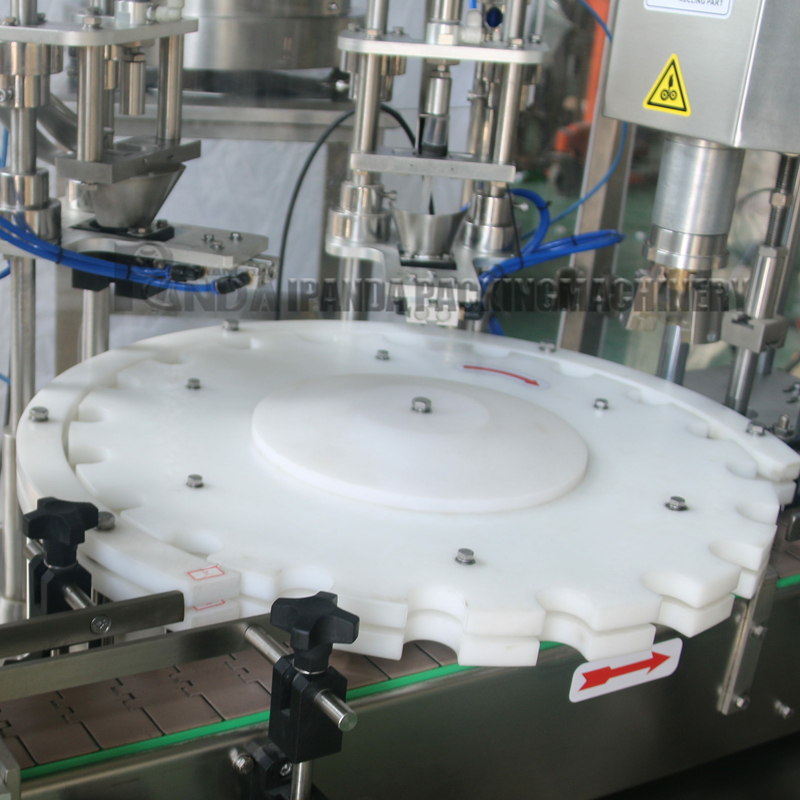

2)Robotic arm capping system, stable and high speed, low failure rate, prevent bottle cap damage.

3)Production speed can be adjusted.

4)Wide range of use, can be used to replace the mold for different bottles filling.

5)The main electrical components of this machine are all used by famous foreign brands.

6)The machine is made of 304 stainless steel material, easy to clean, and the machine meets the requirements of GMP.

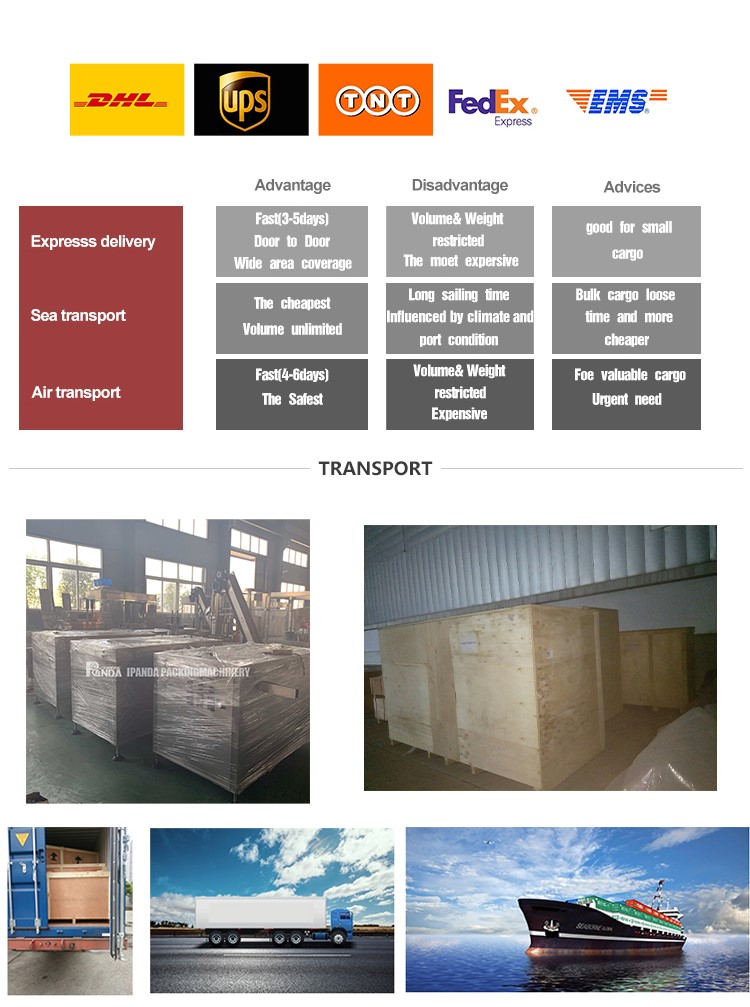

Rotary table, No bottle no filling, No cap auto stop, easy for trouble shooting, No air machine alarm, Multiple parameters setting for different caps.

Filling system: lt can achieve automatic stopping when bottles are full, and automatic starting when bottles are lacked on the belt conveyor.

Adopt SS304 filling nozzles and food grade Silicone tube.It's meet CE Standard.Filling nozzle dive into bottle to fill and rise slowly to prevent foaming.

Capping station

Capping head all will customize according to customer different cap.

Adopt Cap Unscrambler, it's customized according to your caps and inner plugs