Automatic servo motor control shampoo cosmetic cream gel filling line machine

The filling machine adopts the volume measurement method, so that the filling accuracy can reach 100% ± There is no need to control the system due to frequent temperature changes. When filling, put the filling head into the bottle, so that the liquid material will not splash out. The filling nozzle rises slowly with the liquid level. The filling head has a special locking device, so that the filling nozzle will not drip after filling.

Automatic servo filling machine with fast cleaning, fast adjustment, volume metering pump action stepless speed regulation, the whole line adopts intelligent control system, adjust the filling quantity, or change varieties only need to set on the touch screen.

Production line machines

Our factory can provide a complete set of equipment for the filling line, including bottle unscrambler, filling machine, capping machine, capping machine, labeling machine and so on

| Name | Automatic Servo Motor Filling Machine |

| Filling head | 1,2, 4, 6, 8, 10, 12, 16 etc(optional according to speed) |

| Filling volume | 10-20000ml etc(customized) |

| Filling speed | 360-8000bph(customized)

For example 2 nozzles filling machine can fill about 720-960bottles for 500ml bottles/jars |

| Filling precision | ≤±1% |

| Power supply | 380V/220V etc(customized) 50/60HZ |

| Power supply | ≤1.5kw |

| Air pressure | 0.6-0.8MPa |

| Quick wearing parts | sealing ring |

1. The body is mainly made of high-quality stainless steel, beautiful appearance, clean and sanitary, and completely meets the food hygiene requirements;

2. The quick and flexible connection mode makes disassembly and cleaning more convenient;

3. It is light and convenient, and has strong adaptability, and has a variety of anti drip filling heads for selection.

4. The material is driven by the servo to drive the piston to extract the material into the metering cylinder, and then the servo pushes the piston into the container through the material tube.

5. The filling head is equipped with an independent vacuum suck-back device, and the grease is uniformly recovered.

6. All electrical accessories are world famous brands, stable and durable in operation.

7. The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specifications without replacing parts, which can meet the production requirements of multiple varieties and specifications

8. This filling machine widely use for pasty liquid filling, such as the foodstuffs, daily-used chemicals, medicine and other chemical industries.

Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

The servo motor can transmit more than 10000 pulses with one revolution, and the pulse collected from the servo motor knows that the filling amount has reached the set requirement. In order to assure the filling accuracy.

Automatic material filling, 200L storage hopper is equipped with a liquid level device, when the material is lower than the liquid level device, it will automatically replenish the material.

Sensor positioning is accurate, automatic shutdown function, no bottle no filling, automatic shutdown function for accumulated bottles, sensitive response and long life

High quality conveyor

High quality conveyor belt can transfer bottles automatically,it is designed with protective guard which can make products will be transferred stably. We can customize the size according to your needs.

Adopt PLC control, Japanese PLC program control, intuitive man-machine interface, convenient operation, PLC control control, loading picture album

Piston Cylinder

According to customer's need filling volume, customize the volume of piston cylinder. The piston moves up and down in the cylinder, which is converted into rotary motion by the piston connecting rod and crankshaft.

It suitable for high viscosity liquid.

The pneumatic filling nozzle can ensure filling paste faster,it is with anti-dripping design which ensure the machine and production cleanliness. Filling nozzles can be customized, 2 nozzles/4nozzles/6nozzles/8nozzles/10nozzles/12nozzles are customerized. The filling nozzles are specially made to dived into the bottles to avoid leakage and reduce bubble.

factory price Anti-drip Piston Servo Motor Auto Paste Filling Machine is suitable for filling liquid and paste,juice,beverage,drinks,milk,makeup remover etc.It is widely used in drinks,cosmetics,daily chemical and pharmaceutical industries.

Company information

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

Before order service

We will according to your requirement make details quotation for you. We can send you some our machine running video similar to your product. If you come to china,we can pick you up from airport or station near our city.

After order service

We will start to make machine,and take some picture by 10 days of our production process .

Our engineer can design the layout according to your requirement.

We will supply commission service if customer need.

After-sales service

We will testing machine ,and take some video and picture to you if u not come to china inspect machine.

After testing machine we will packing machine ,and delievery container on time.

We can send our engineer to you country help you install and testing machine.we can training you technical staff free until they can running machine independent.

Our company will give you all machine with 1 years guaranteen.In 1years you can get all spare parts free from us.we can send you by express.

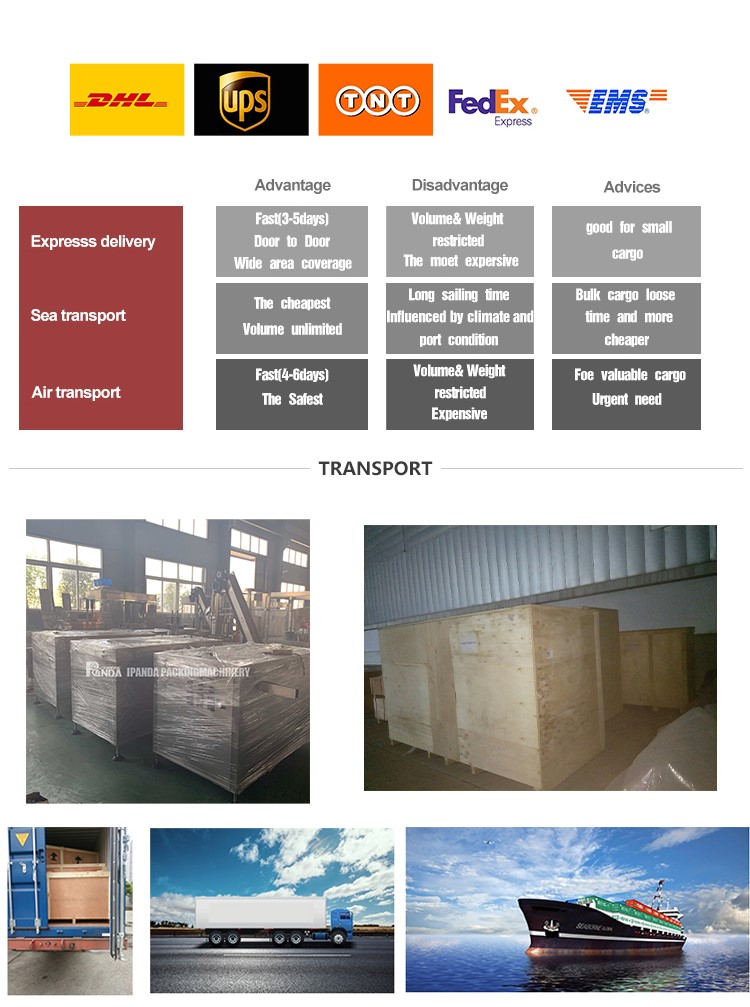

Packaging Details:

Filling machine packed by packed with seaworthy strong wooden case as the general export package. We use carton as inner packing, in case of damage in the course of carriage, we also can pack it according to clients' requirements

FAQ

Q1: What is your company's main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q4:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q5:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q6:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni cal drawing, but also can he new machine according to your requirements.

Q7:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.