Automatic Medicine Vial Blood Reagent Test Tube Pharmaceutical Filling Machine

This machine is mainly used for automatic bottle unscrewing and capping (capping) of plastic bottle reagents. This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design; working table is protected by stainless steel material, and the whole machine meets GMP requirements. The transmission of this machine adopts mechanical transmission, the transmission is accurate and stable, there is no air source pollution and there are errors in the coordination of various mechanisms. When working, the noise is low, the loss is low, the work is stable, and the output is stable. It is especially suitable for small and medium batch production.

| Accuracy | ±2% |

| Speed | 70-90 bottles/min |

| Upper cover mode | Manipulator the upper cover |

| Voltage | 220V/50Hz |

| Power | 4 KW |

| Dimensions | 2400mm×1200mm×1700mm |

| Weight | 580kg |

Remark: In view of our products model different ,widely used in many industries ,in order to improve communication efficiency .so pls note the size weight and name of testing product before send us inquiry .so we can choose the suitable one for you ,send detail and quotation to your email .thank you for your understanding .

1.The oscillator is used for bottle management.and an independent sound insulation system is added to effectively reduce the interference of noise to users.

2.The peristaltic pump is used for filling,which can effectively avoid cross pollution.Our company adopts the independently developed program to control the imported servo motor drive, combined with the high-precision pump head (domestic or imported), and the accuracy can be controlled within plus or minus 2%.

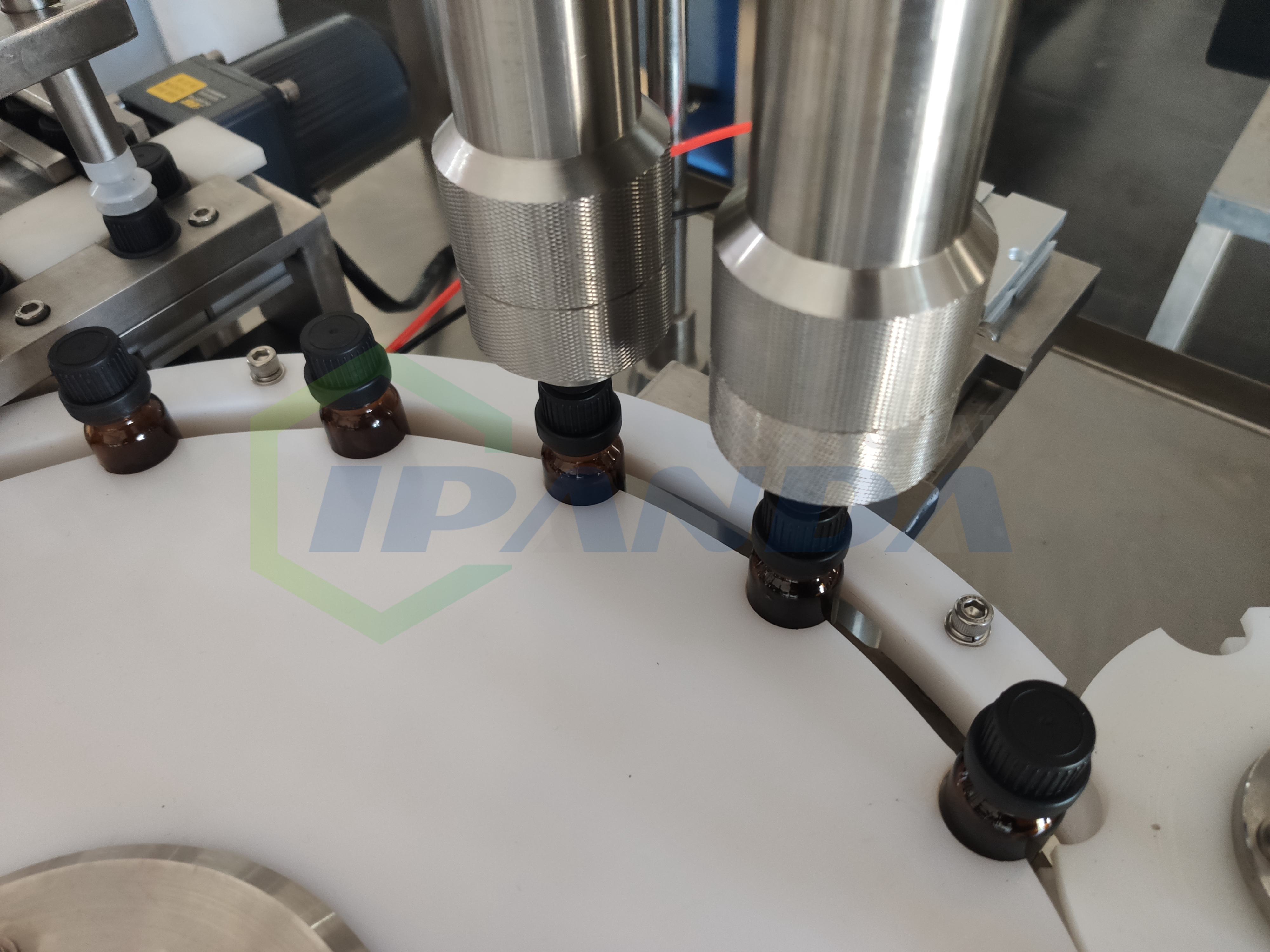

3.The vacuum manipulator is used for cover removal,Accurate positioning, not easy to fall off the cover. The cover is screwed with imported servo motor,and the torque is adjustable and controllable.

This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design;

The high-precision peristaltic pump is used for filling, with high precision and no cross-contamination of materials; the structure of the pump adopts a quick-connect disassembly mechanism for easy cleaning

Put the inner plug-put the outside cap-screw the cap

Using a magnetic torque capping head, the capping torque is steplessly adjustable, with a constant torque capping function,This machine to correct the tilted cap, not to damage the cap, and the sealing is tight and reliable;

Cap vibrating plate used to arrange cap automatically

All action is controlled by PLC and Touch screen. The surface of machine is SUS304, material contacted with liquid is 316L stainless steel, can be connect with labeling machine.