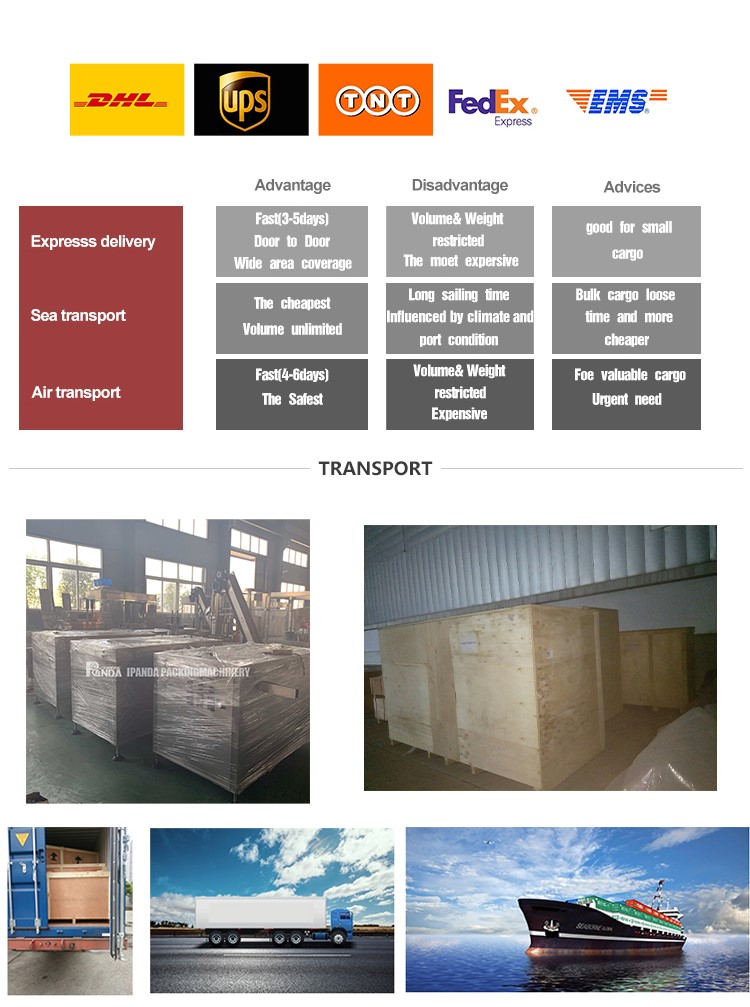

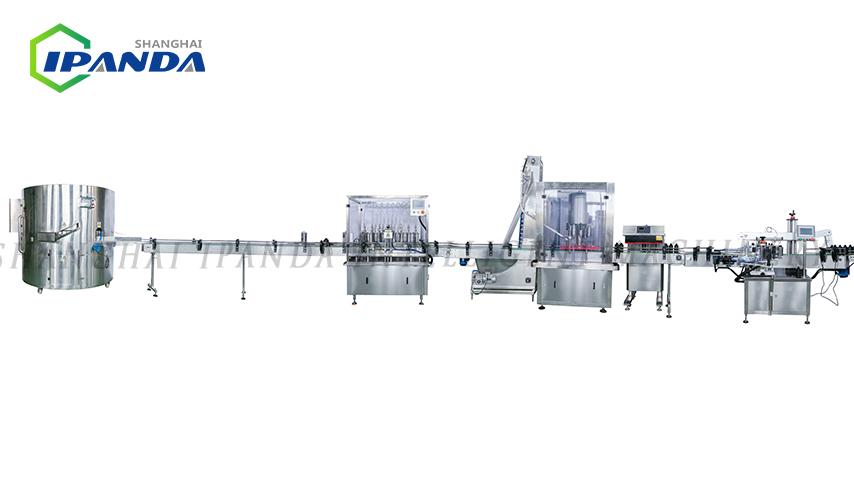

Automatic Linear Chemical Liquid Filling and Capping Packing Machine

High Viscosity Liquid Filling Machine is the new-generation improved volumetric filling machine which is Suitable for material:viscous liquid

The whole machine uses the in-line structure and it is driven by the servo motor. Volumetric filling principle can realize the high precision of filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjustment easier. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.

Automatic bottle uncrambler--- Filling machine--- Capping machine---Aluminum foil sealing machine --- Labeling machine

|

Machine |

Item |

Specification |

|

Bottle uncrambler |

Function | Organize and collect the bottles |

| Bottle Application | Pet bottle,Plastic bottle | |

|

Filling Machine |

Application | Beach,Liquid soap, shampoo, lotion, cream, detergent etc. |

| Filling Volume | 50-500ml, 100-1000ml, 500-5000ml can be customized | |

| Filling Speed | 1800-2400BPH (customized) | |

| Filling Nozzle | Six head(customized) | |

|

Capping Machine |

Application | Screw caps, pump heads etc. |

| Applicable cap diameter | 20~55mm (customized) | |

| Capping Speed | 1200-3000BPH (customized) | |

| Driven Type | Electric | |

| Speed Control | Interval control, the speed is adjustable. | |

|

Aluminum foil sealing machine |

Bottle height | 35~250mm |

| Bottle diameters | Φ20~φ80mm | |

| Application | Round bottles,flat bottle square bottle | |

| Applicable Label Height | 20-100mm (customized) | |

| Label roll inner diameter | Φ76.2mm (customized) | |

|

Labeling machine |

Application | Round bottles,flat bottle square bottle |

| Applicable Label Height | 20-100mm (customized) | |

| Label roll inner diameter | Φ76.2mm (customized) | |

| Max. label roll outer diameter | φ350mm (customized) | |

| Labeling Speed | 2000-3000BPH |

1. PLC plus man-machine interface, touch operation. Self-diagnosis of fault alarm is clear at a glance.

2. The center-feeding die head completely eliminates the product confluence line, and it is convenient and quick to change the material and color.

3. The moving mold adopts double linear guide rails and center clamping. The force is evenly applied to ensure a smooth cut of the product.

4. The hydraulic system adopts proportional hydraulic control and is equipped with imported hydraulic components, which is accurate, stable and energy-saving.

5. The high-speed, high-efficiency, low-energy plasticizing system of the automatic blow molding machine, with excellent mixing uniformity, to ensure the purity of the product.

Bottle Unscrambler Part

The main motor speed reducer applies torque limit mechanism to avoid harming the machine when trouble happens.

Filling part:

ANTI-DROP Filling Nozzles

Equipped with SUS316L long special designed no-drop filling nozzles, which can protect the cylinder on the top being damaged material; Design different size of filling nozzles

SERVO MOTOR Control Filling Volume

SUS304 frame, Round SUS316L PISTONS,TECO servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen

Capping machine and aluminum foil sealing machine

Modular manufacturing,easy to assemble or disassemble,and easy to maintain.Screw the cap at high speed and efficiency is high,Safe and reliable.

Standing Style Incuction Foil sealing machine is widely applied for Fuel additive, medicine bottle, sport bottle, honey jar, medicine bottle ,yogurt bottle, chili sauce and so on.

Capping part

It adopts variable frequency speed regulation, mechanical capping mechanism with complete functions;

The appearance structure of the whole machine is 304 stainless steel, which has good performance, easy operation and beautiful appearance;

Labeling Part

This double side labeling machine model is perfectly suitable for applying labels on both sides of bottles and containers of various shapes and sizes

ABOUT

COMPANY OVERVIEW

Growing Your Skills

Providing Best Talent Solution For

We Have More Than 20+ Years Practical Experience

- Dedication to Research & Development

- Experienced Management

- Better understanding of Customer requirement

- One Stop solution provider with Broad Range Offering

- We can supply OEM&ODM design

- Continuous Improvement with Innovation

FAQ

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory, we supply the factory price with good quality, welcome to visit !

Q2: What's your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The delivet time is based on the exact machine you confirmed.

Q4: How do you offer technical support?

A4:

1.Technical support by phone, email or Whatsapp/Skype around the clock

2. Friendly English version manual and operation video CD disk

3. Engineer available to service machinery overseas

Q5:How do you work your after sales service?

A5:Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately. And You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.

Q6: How about the spare parts?

A6: After we deal down all the things , we will offer you a spare parts list for your reference.