Overview:

This machine is one of the traditional filling stoppering and capping equipment, advanced design, reasonable structure, can automatically complete filling,stoppering and capping process, is suitable for eye drop,e-liquid,and other vial bottles such as, no bottle no filling, no bottle no stoppering(plug), and other functions. Can be used stand-alone, and also can be used for filling line. This machine completely accords with the new GMP requirements.

Features:

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

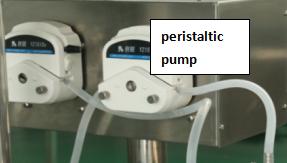

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

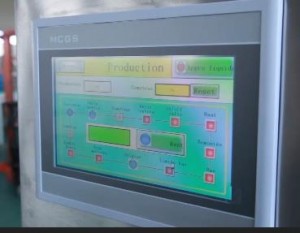

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6. Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

|

Main parameter of the machine

|

| Name |

Filling capping machine |

Filling volume |

5-250ml,can be customized |

| Net weight |

550KG |

Filling heads |

1-4 heads,can be customized |

| Bottle diameter |

Can be customized |

Filling speed |

1000-2000BPH,can be customized |

| Bottle height |

Can be customized |

Voltage |

220V,380V ,50/60GZ |

| Filling accuracy |

±1ml |

Power |

1.2KW |

| Bottle material |

Glass ,plastic bottle |

Working pressure |

0.6-0.8MP |

| Filling material |

Eye drop,e-liquid,cbd oil |

Air consumption |

700L per hour |

The detail pictures:

We adopt SS304 Filling nozzles and food grade slicone tube

Cap sorter is customized for your cap

It unscramble the caps and convey to capping part of the machine.

Inserting dropper-putting cap

Adopt magnetic torque screwing capping

Adopt Peristaltic pump,It’s suitable for fruid liquid filling.

Adopt PLC control,touch bottle operation, simple and convenient operation;

Shanghai Ipanda Intelligent Machinery Co. ltd is a professional manufacturer of all kinds of packaging equipment. We offer full production line including bottle feeding machine, filling machine, capping machine, labeling machine, packing machine and auxiliary equipment to our customers.

We focus on producing various kinds of filling production line for different products, such as the capsule, liquid, paste, powder, aerosol, corrosive liquid etc, which are widely used in different industries, including food/beverage/cosmetics/petrochemicals etc. Our machines are all customized according to customer’s product and request. This series of packaging machine is novel in structure, stable in operation and easy to operate.Welcome new and old customers letter to negotiate orders, the establishment of friendly partners. We have customers in Unites states, Middle east, Southeast Asia, Russia etc. and have gained good comments from them with the high quality as well as good service.

Why Choose Us

Dedication to Research & Development

Experienced Management

Better understanding of Customer requirement

One Stop solution provider with Broad Range Offering

We can supply OEM&ODM design

Continuous Improvement with Innovation

FAQ

Q1: What is your company’s main products?

Palletizer, Conveyors, Filling Production line, Sealing machines, Cap�ping Machines, Packing Machines, and Labeling Machines.

Q2: What is delivery date of your products?

Delivery date is 30 working days usually most of the machines.

Q3: What is payment term? Deposit 30% in advance and 70% before shipment the machine.

Q5:Where are you located? Is it convenient to visit you? We are located in Shanghai. Traffic is very convenient.

Q6:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3. The electrical pneumatic components are from the world famous companies,such as Germany^ Siemens, Japanese Panasonic etc.

4. We will do strict test running after the machine is finished.

5.0ur machines are certified by SGS,ISO.

Q7:Can you design the machine according to our requirements? Yes. We not only can customize the machine according to your techni�caldrawing, but also can he new machine according to your requirements.

Q8:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your.